RATCHET WHEEL

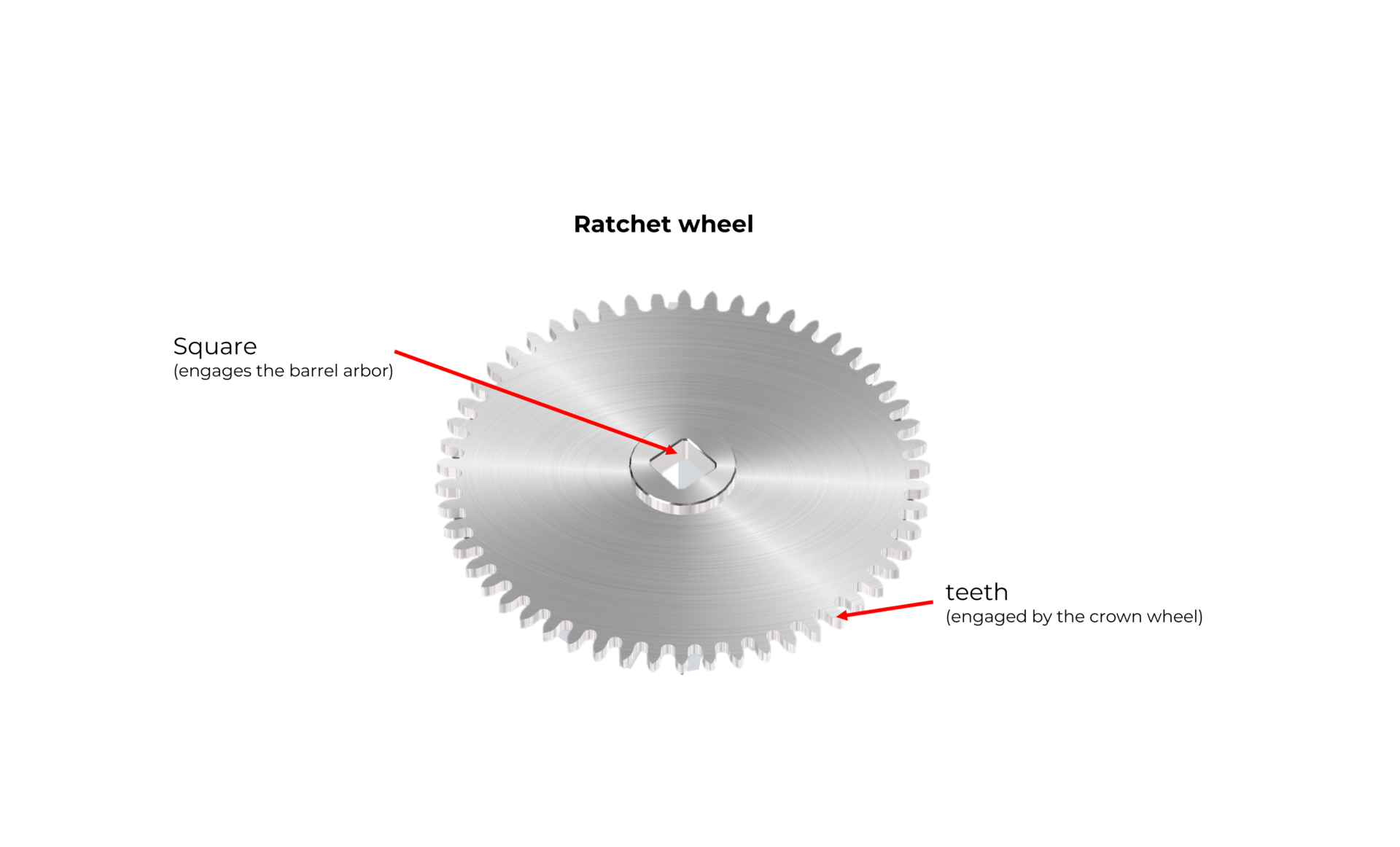

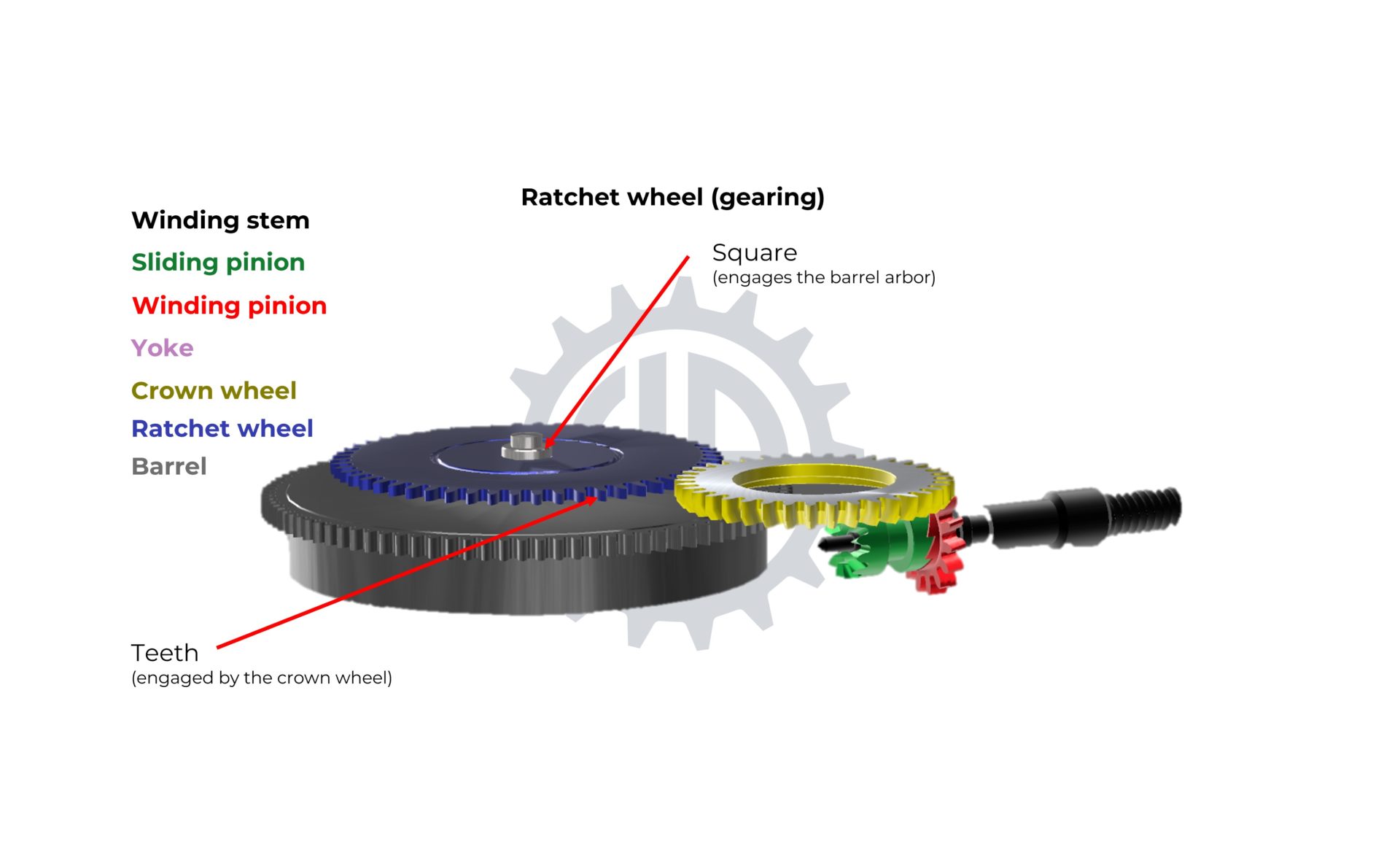

The ratchet wheel is the final component in the kinematic chain of the winding mechanism. Because of the torques involved in winding the watch, and therefore the stresses in its teeth, the ratchet wheel must be strong and is almost always made of steel. Technically, the ratchet wheel is a disc with teeth cut around its periphery and a square-sectioned hole at its centre.

The barrel pivots between the plate and its bridge. In most constructions, the barrel arbor extends above the bridge’s surface. The emerging part of the barrel arbor has a square opening. Upon fixing the barrel with its bridge, the square opening in the centre of the ratchet wheel fits onto this square section of the arbor. The ratchet wheel is then directly screwed onto the barrel arbor. In other constructions, the ratchet wheel can also be located under the barrel bridge and held between two supports, without any screws. However, the operating principle remains identical. The ratchet wheel rotates by the energy received from the winding mechanism, driven directly by the crown wheel. Its square fit drives the barrel arbor in a rotary movement that winds the barrel spring, putting it under tension and thus providing the watch with the energy needed for power reserve. To prevent the accumulated energy in the drum from escaping through the crown, a click system directly connected to the ratchet wheel allows only unidirectional rotation, capturing the energy at the heart of the barrel drum, leaving the gear train as the only exit.

Contrary to most components of the winding mechanism that appeared with Adrien Philippe’s invention in 1842, the ratchet wheel is as old as the use of a flat spring (barrel spring) as a driving force. The date and origin of the invention (or application) of a flat spring as a driving force are unknown, however, the first clocks with such a “motor” appeared as early as the 15th century. From the outset, it was necessary to ensure that the force of the spring did not escape through the winding mechanism. To contain this energy in the drum and force it to “escape” through the gear train, a toothed wheel directly engaged by a square is fixed to the barrel arbor. The locking system (of the pawl and its spring) blocks the ratchet’s teeth, allowing it to turn only in one direction (winding) and thus containing the force of the barrel. This medieval principle remains unchanged and is present in all mechanical watches.

Made exclusively from steel, the ratchet wheel is relatively easy to manufacture. According to traditional methods, a lathe equipped with a dividing head allows for all its manufacturing stages. Turning operations come first. The teeth are preferably cut successively on the same lathe without interruption to ensure the concentricity of the assembly (turning and teeth). These operations are carried out with a milling cutter and a dividing head mounted on the lathe. Once cut from its bar, the ratchet can be made thicker. The square opening for its fit can be filed from a previously drilled circular hole at the centre of the ratchet wheel. Heat treatments and decoration (usually a sunbursting) complete the manufacturing steps according to traditional methods.

As with most circular components of small diameter, the automatic lathe is the best means of producing ratchet wheels using the industrial method. All machining operations (turning, milling, cutting) can be performed in a fast cycle without any difficulty. As always on an industrial scale, finishing and decoration will be done by hand or industrially, depending on the required level of finishing and the watch’s range.