WATCHMAKING MACHINES AND TOOLS

While many contemporary artisans replicate the same actions and use the same tools as their 18th-century predecessors, watchmaking machines and tools have continuously evolved over the centuries. Substituting hydraulic power with electricity significantly increased production rates and capacities, allowing brands to move away from riversides. The late 19th-century industrial era brought one of the greatest revolutions in horology: the interchangeability of components. This concept enabled the industrialization of production, therefore providing cost reduction, while enhancing the reliability and durability of watches. To achieve this, machines were automated, which increased precision. Finally, the digital era has become indispensable in all horological applications, contributing to their rapid advancement.

Neither a century-old tool nor the most “intelligent” automated machines are of any use without skilled people to operate them, however.

HAND OPERATED TOOLS

This chapter covers the light tools used directly by watchmaking professionals. These tools generally have a specific purpose and are used for a wide range of tasks, including manufacturing, decorating, and cleaning as well as inspecting and measuring components.

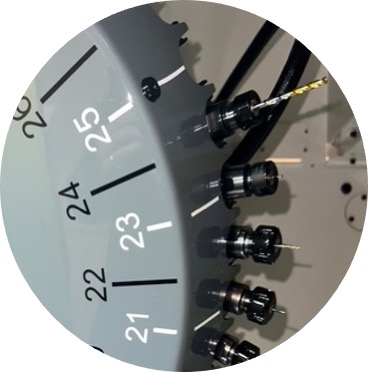

CUTTING TOOLS

These are tools designed to shape a component by removing material (drilling, turning, milling). They can be operated manually (using a hand tool such as a chuck or a bow drill) or by a machine (such as a lathe, milling machine, automatic lathe, or drill press, etc.).

MACHINES

This chapter lists all the machines that can be used in watchmaking, whether they are artisanal and manual or industrial and digitally controlled machining centres.

BECOME A CONTENT CONTRIBUTOR

HOROPEDIA is a participative knowledge platform and we invite all those who wish to contribute to this adventure of sharing watchmaking knowledge to join us.

It can be additional explanations, images or other illustrations or terms not yet identified that deserve to be.