BASIC PRINCIPLES OF MECHANICAL WATCH FUNCTIONING

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

Based on the observation of celestial bodies, the projection of shadows (gnomon, sundial) and the flow of fluids (clepsydra, hourglass), measuring instruments became mechanical as early as the 13th century (clocks). Although the first pocket watches appeared during the 16th century, it wasn’t until the 18th century that they became reliable and widespread. Most manufacturing methods and mechanical principles from that era remain in use today, although they may have evolved in line with the development of knowledge and technology.

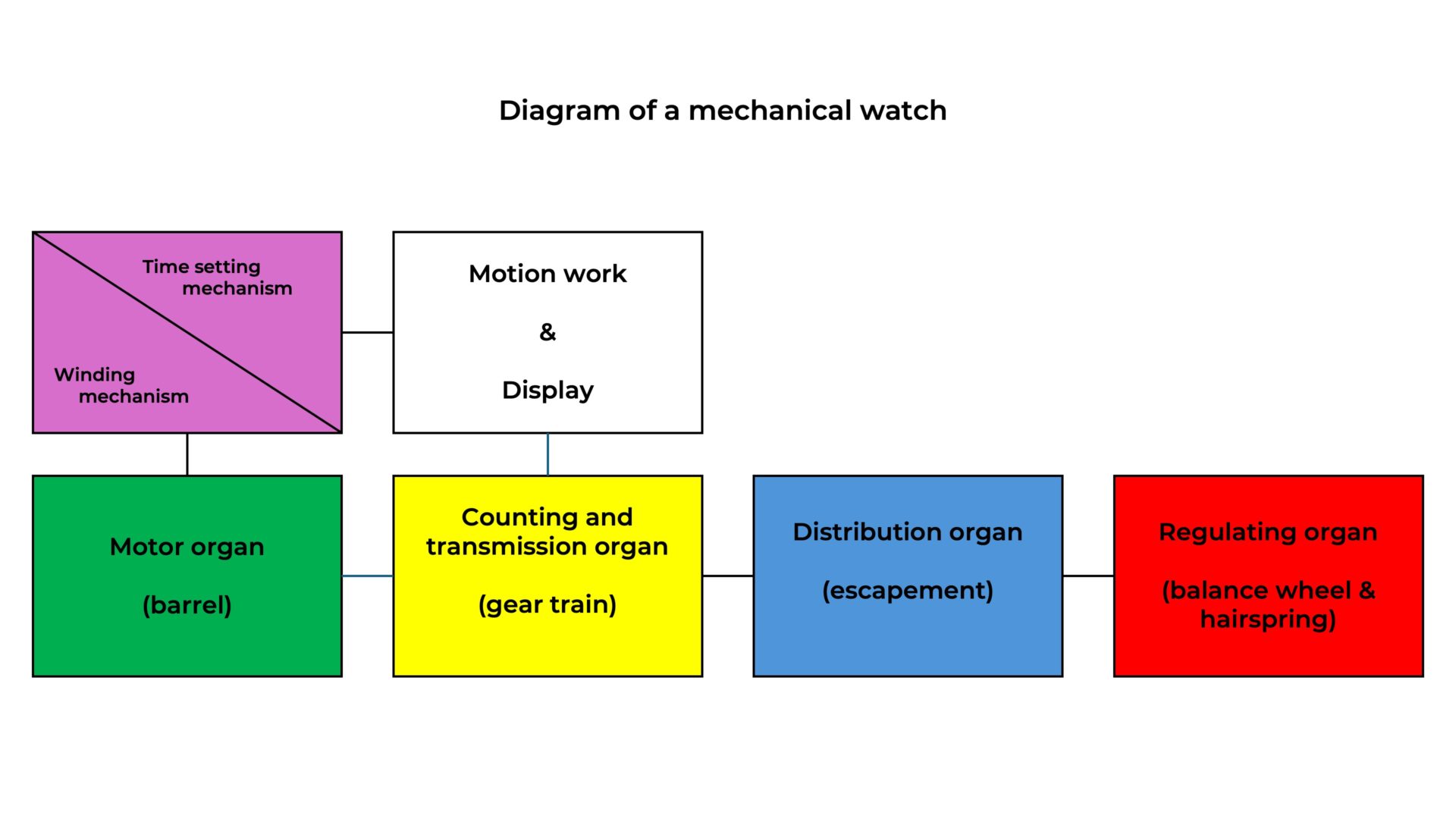

A mechanical movement can consist of over several hundred components. To better understand how it works and the various interactions between these components, they should be divided into several different organs, each bearing a specific role.

The different organs of a mechanical movement are the following:

THE MOTOR ORGAN (barrel)

Role: Positioned at the beginning of the movement’s kinematic chain, the mainspring’s role is to store the energy required for the movement’s operation and gradually release it.

Main Components: The barrel (comprising the mainspring itself, mainspring, barrel arbor, and cover).

THE COUNTING AND TRANSMISSION ORGAN (gear train)

Role: The gear train’s role is to convey the energy from the mainspring to the regulating organ via the escapement, mechanically dividing the frequency to drive various indications. For example, the seconds wheel completes a turn in one minute, while the centre wheel (which carries the minute hand) completes its turn in one hour, etc.

Main Components: The number of wheels in the gear train may vary, but it generally includes centre wheel, second wheel, the seconds wheel and the escapement.

THE DISTRIBUTION ORGAN (escapement)

Role: The escapement serves two distinct functions. First, it stops the gear train when the balance wheel is in its free oscillation phase. Periodically (between 5 and 10 times per second), it releases the gear train and imparts brief impulses to the balance wheel to sustain the oscillations of the regulating organ (the balance wheel-hairspring).

The second function is to transform the linear movement of the gear train (continuous rotation) into an oscillating motion (the oscillations of the regulating organ).

Main Components: In a Swiss lever escapement, the components include the escape wheel, pallet fork, and double plate. Although the pallet fork is fixed solidly on the balance wheel’s staff (the regulating organ), it is the last component in the escapement’s kinematic chain and is an integral part of this organ.

THE REGULATING ORGAN (balance wheel-hairspring)

Role: The regulating organ responsible for ensuring a watch’s accuracy. Regardless of the type of a watch or a clock and its construction, the regulating organ is always an oscillator. The higher the frequency of an oscillator, the more accurate the watch will be. Although there have been attempts to achieve very high frequencies, the regulating organs of mechanical watches generally oscillate between 2.5Hz and 5Hz.

Main Components: The balance wheel and hairspring. This tandem, often referred to as the balance wheel-hairspring, constitutes the regulating organ.

Balance wheel:

Hairspring:

WINDING AND SETTING MECHANISM

It allows the user to provide energy to the mainspring and set (at a minimum) the time displayed by the watch.

Winding mechanism:

Time setting mechanism:

THE DISPLAY & MOTION WORK

It shows the various information provided by the movement.

Any additional system or mechanism beyond this base is referred to as a “complication”.