MANUFACTURING TECHNOLOGIES

Depuis la dernière décennie du 20ème siècle, de nouvelles technologies révolutionnent ou sont en passe de révolutionner la fabrication de certains composants horlogers. Bien souvent, de nouveaux alliages, ou des matériaux jusqu’alors inédits y sont associés. Bien qu’impliquant fréquemment des équippements complexes, ce chapitre explique davantage leurs procédés de fabrication plutôt que les différentes machines ou équippements qu’ils nécessitent.

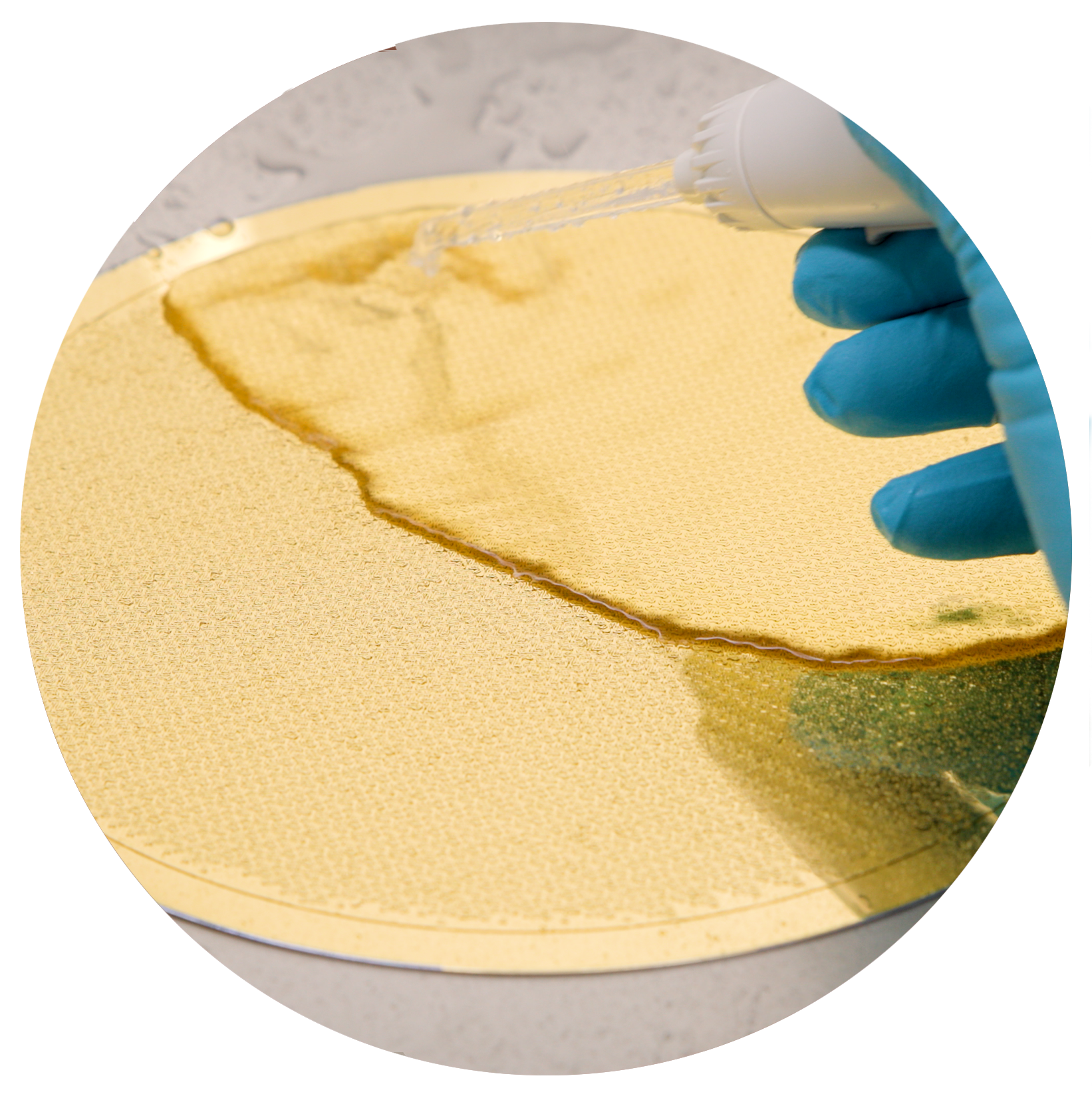

MANUFACTURING COMPONENTS BY ELECTROFORMING TECHNOLOGY (UV-LIGA)

Emerged in 1998, this additive manufacturing technology combines lithography (through UV exposure) and electroplating. The acronym UV-LIGA directly refers to this process. Traditional manufacturing methods generally involve the use of specific types of machinery (machining centres, stamping presses, or electrical discharge machining). The UV-LIGA technology, however, entails a manufacturing process divided into several distinct stages.

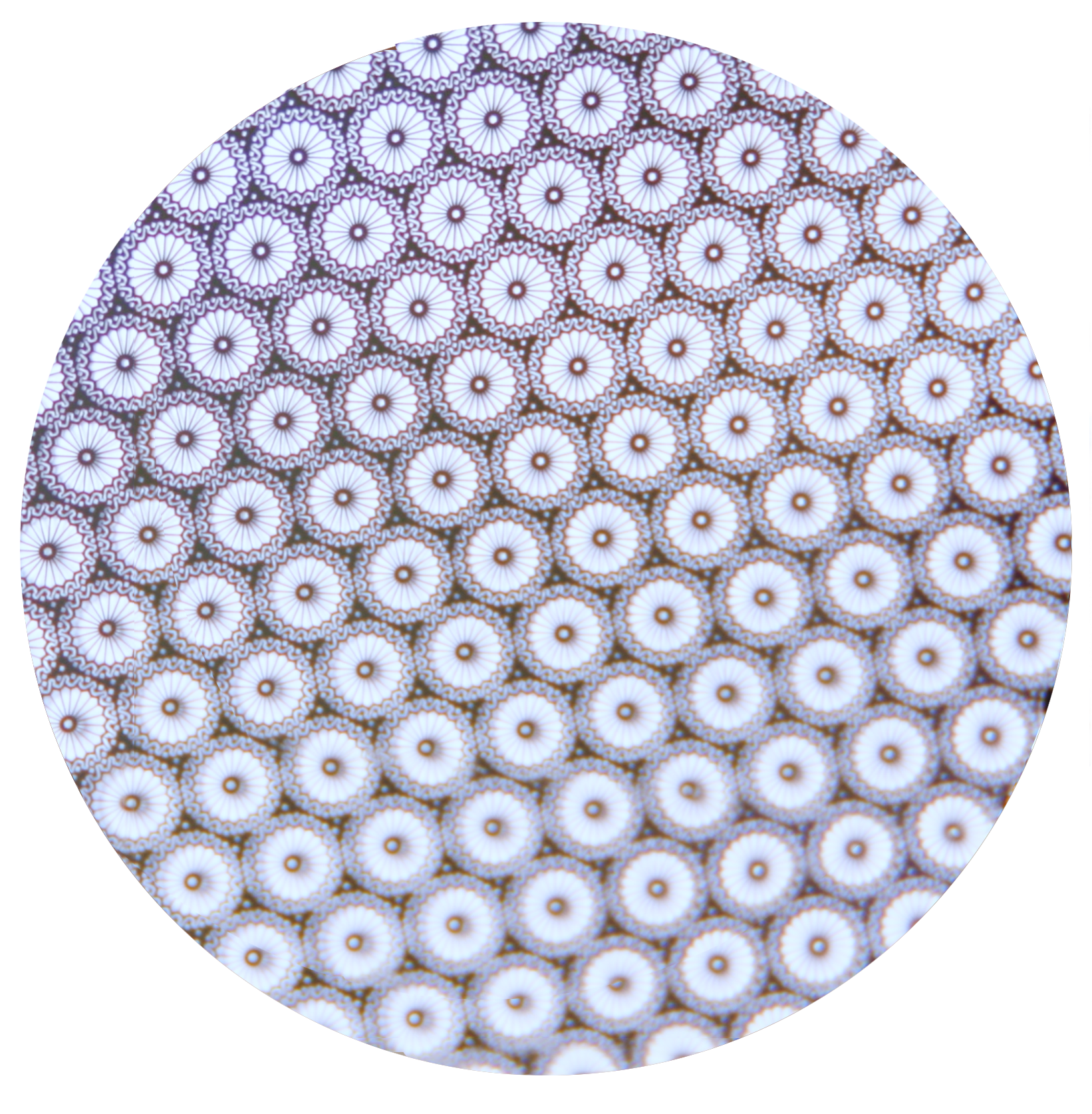

MANUFACTURING SILICON COMPONENTS BY DEEP REACTIVE ION ETCHING (DRIE)

Silicon and its manufacturing using deep reactive ion etching (DRIE) were introduced in watchmaking as early as 2001. The properties of silicon offer numerous advantages, making it a favoured material for the production of escapements and hairsprings in particular.

MANUFACTURING COMPONENTS BY SELECTIVE LASER MELTING (SLM)

This is an additive manufacturing technology (3D printing) performed by laser fusion of metallic alloys. It opens new horizons in terms of style, design, and technical sophistication.