BARREL ARBOR

Figure 1: Exploded view of a barrel (manual winding)

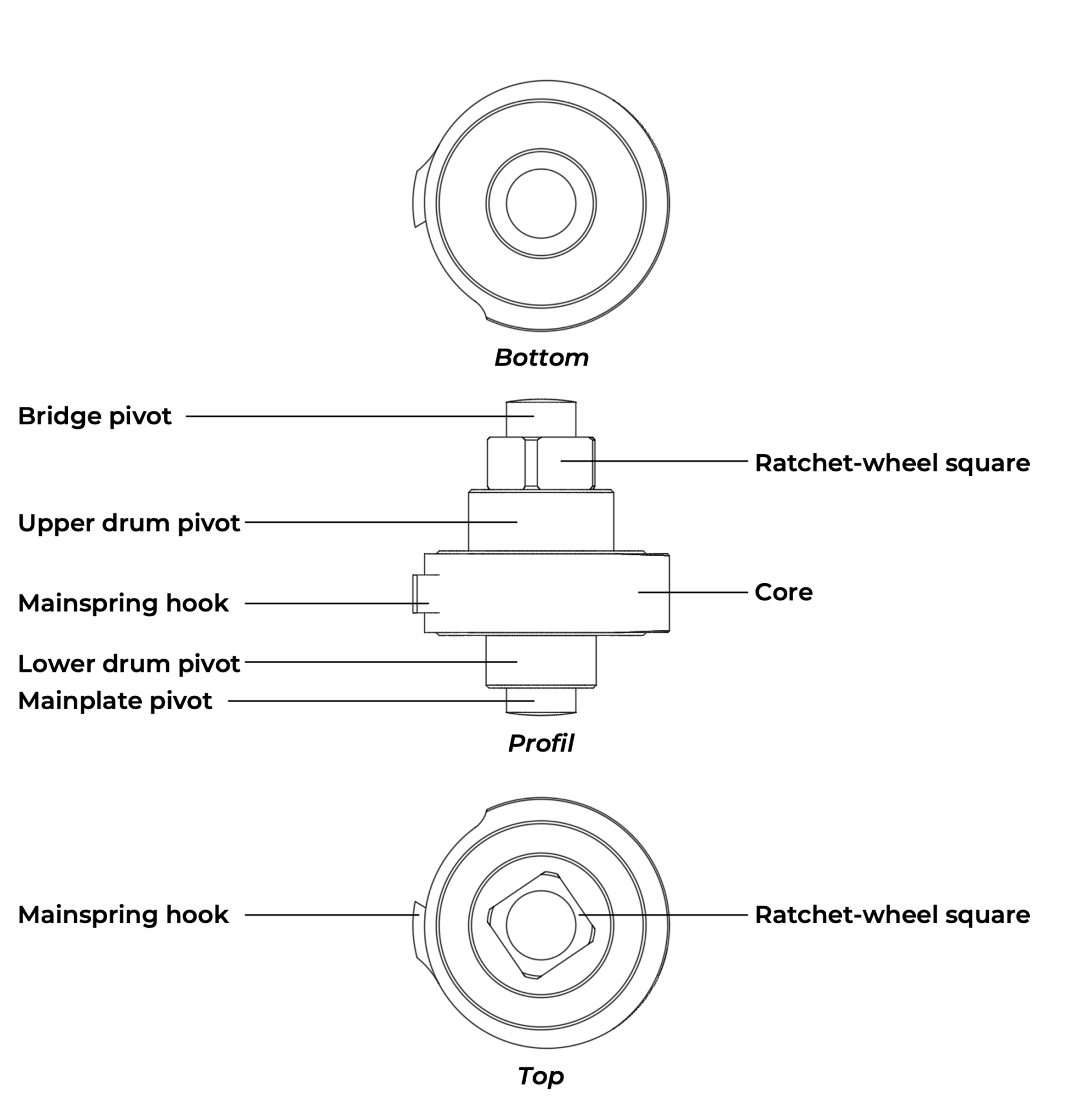

Figure 2: Plan of a barrel arbor

The barrel arbor is part of the driving mechanism and forms the central axis of the barrel. It usually pivots between the mainplate and the barrel bridge. Positioned closest to the energy source, the barrel arbor is the axis within a watch subjected to the greatest forces (torque). It is therefore made of steel, and its pivots are of large diameter.

At the centre of the arbor’s vertical plane is its widest section: the hub. Around the circumference of the hub is the hook to which the inner end of the mainspring is attached. The height of the hub corresponds to the height of the mainspring, with a slight additional margin to allow the spring to unwind freely. On either side of the hub are two pivot shanks that allow the barrel drum to pivot freely around the arbor, while the latter remains fixed in place, held by the winding click.

The lower part of the barrel arbor ends in a pivot that connects it to the mainplate. The ratchet wheel may be positioned below (as in our example) or above the barrel bridge. The square section of the barrel arbor, which engages with the ratchet wheel, extends directly from the upper part of the drum and ends in the upper pivot connected to the barrel bridge when the ratchet wheel is located beneath the bridge. If the ratchet wheel is situated above the barrel bridge, the positions of the square and the upper pivot are reversed. In such a case, the upper part of the barrel arbor is drilled and tapped, allowing the ratchet wheel to fit onto its square and be screwed into place.

Although the barrel arbor is a generously sized shaft by watch movement standards, its manufacture presents two key challenges: shaping the hook on the periphery of the hub, and forming the square intended to receive the ratchet wheel.

All machining operations, however, can be carried out on a lathe (such as a Type 70). Aside from the two aforementioned complexities, the barrel arbor is a relatively simple component, consisting of a stack of concentric turned sections. Both the hook on the hub and the square can be machined either by milling on an equipped lathe or through a subsequent operation on a milling machine. The more daring might even file the square by hand.

Once fully machined, the pivots can be burnished, and the entire arbor is polished to protect it from corrosion and to minimise friction with the other components of the barrel.