General description

In general, the term collet refers to a split ring that can pivot more or less freely around the axis on which it is fitted. For example, collets are found on the rim of certain variable-inertia balance wheels.

In mechanical movements, the collet is the connecting element between the hairspring and the balance wheel staff. It is one of the components of the regulating organ and plays an essential role in adjustment operations.

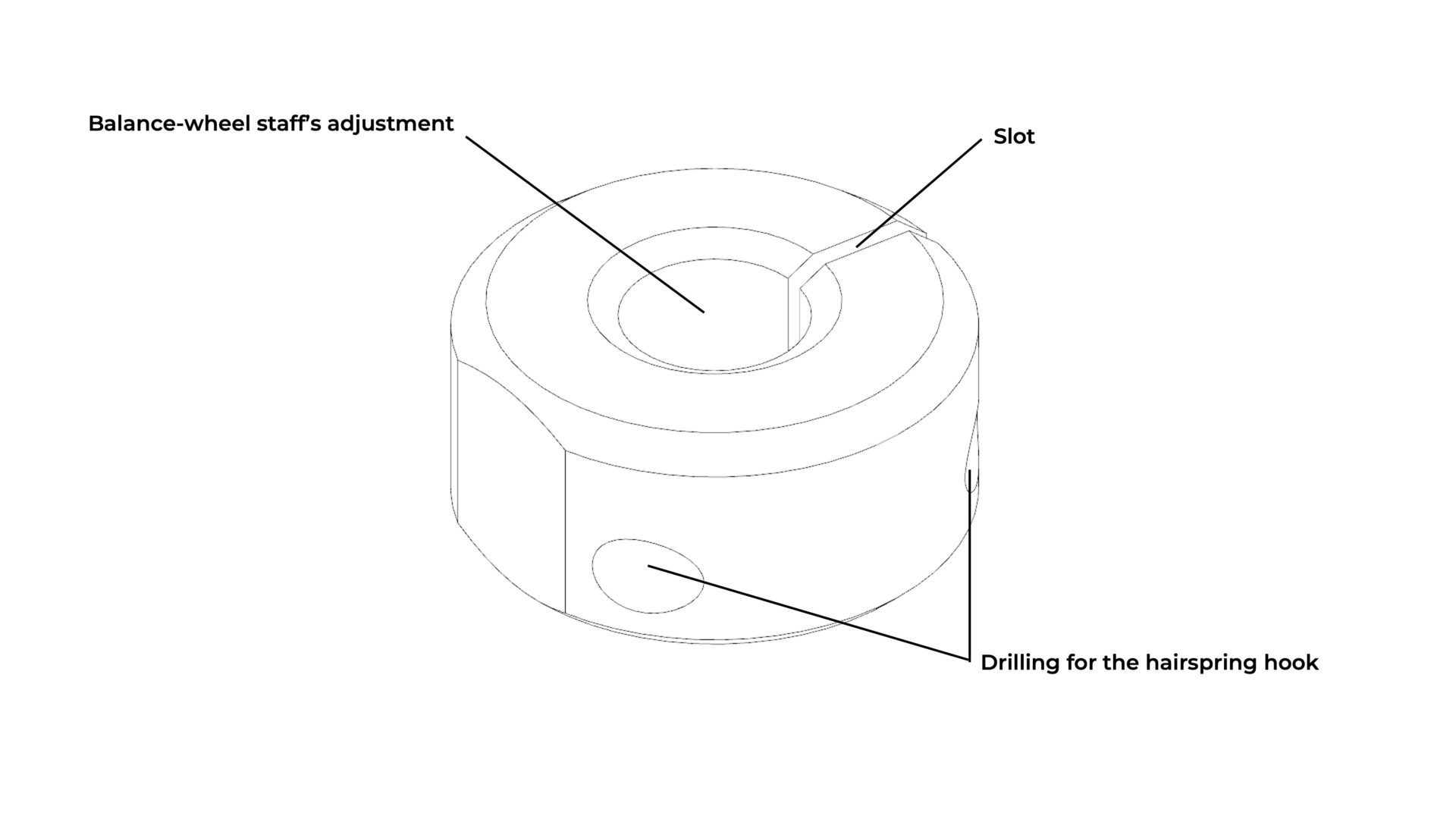

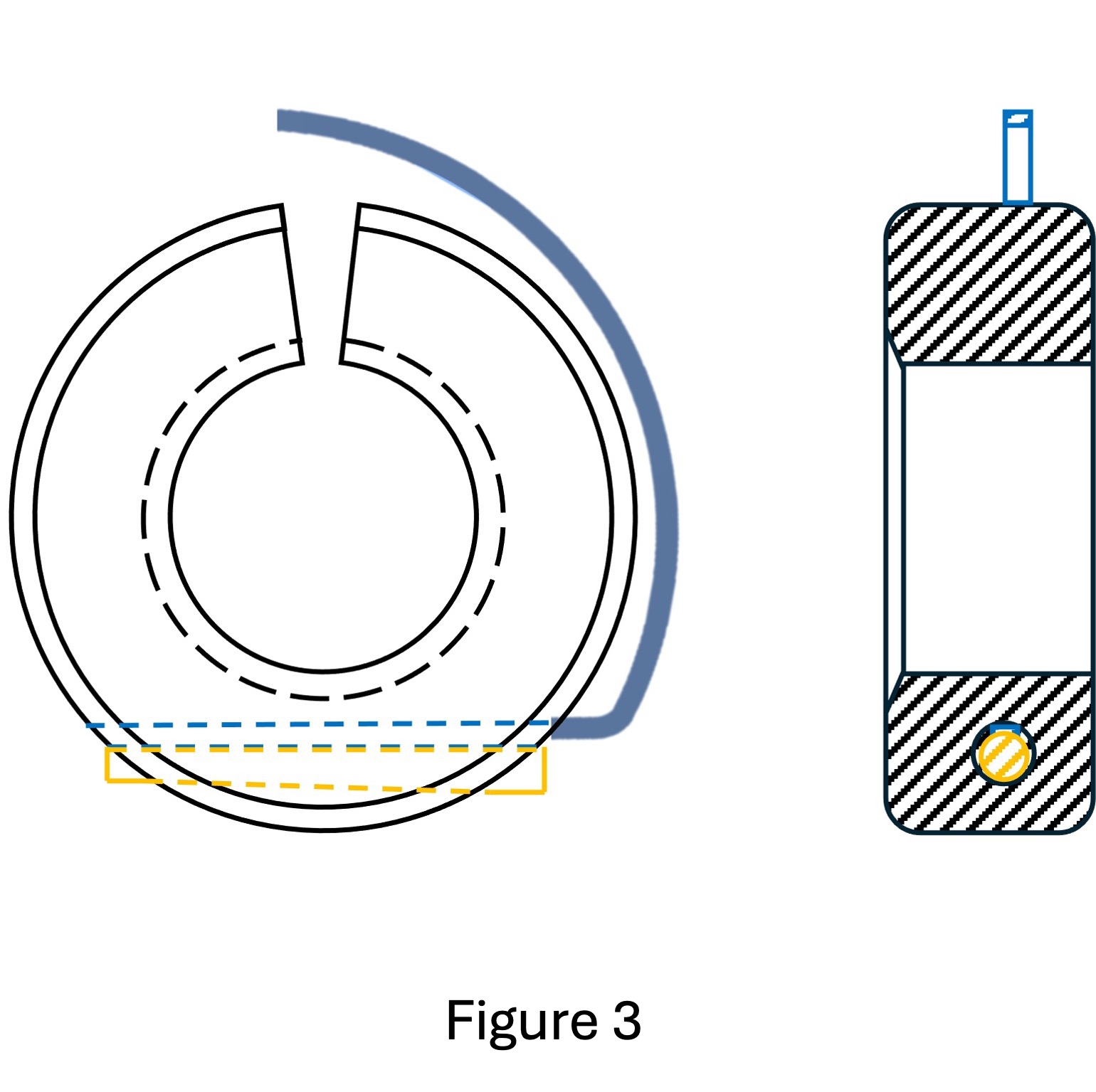

It is a split brass ring with an off-center transverse hole intended to receive the hairspring hook. When the hairspring stud is properly formed, it is inserted into the collet’s transverse hole. Once correctly positioned, it is secured there with a brass pin (Figure 3).

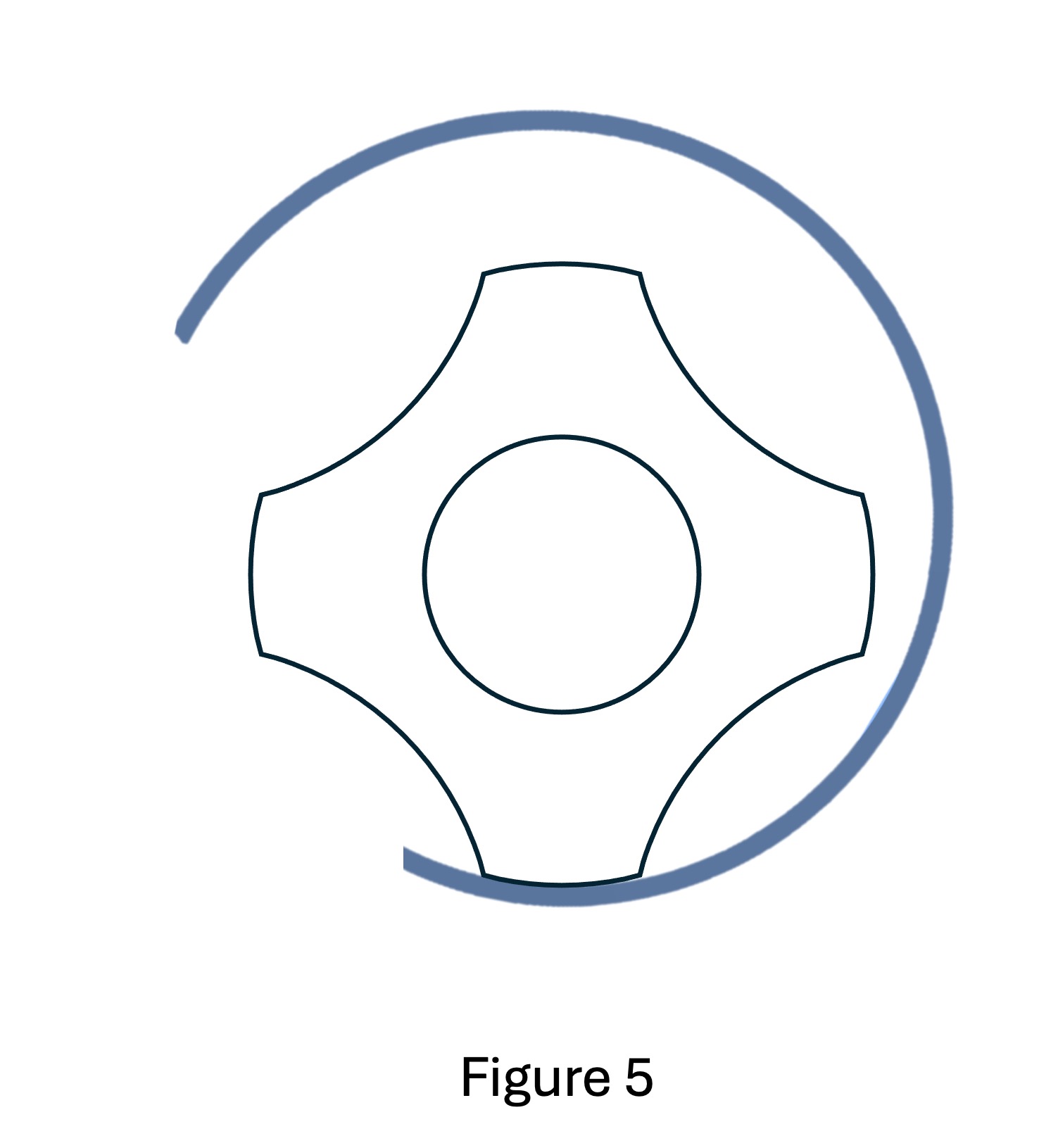

Another industrial colleting method consists of attaching the hairspring to the collet by laser welding (Figure 5). As with Greiner colleting, this method does not allow correction of the attachment point. However, it presents a lower risk of deforming the first coil.

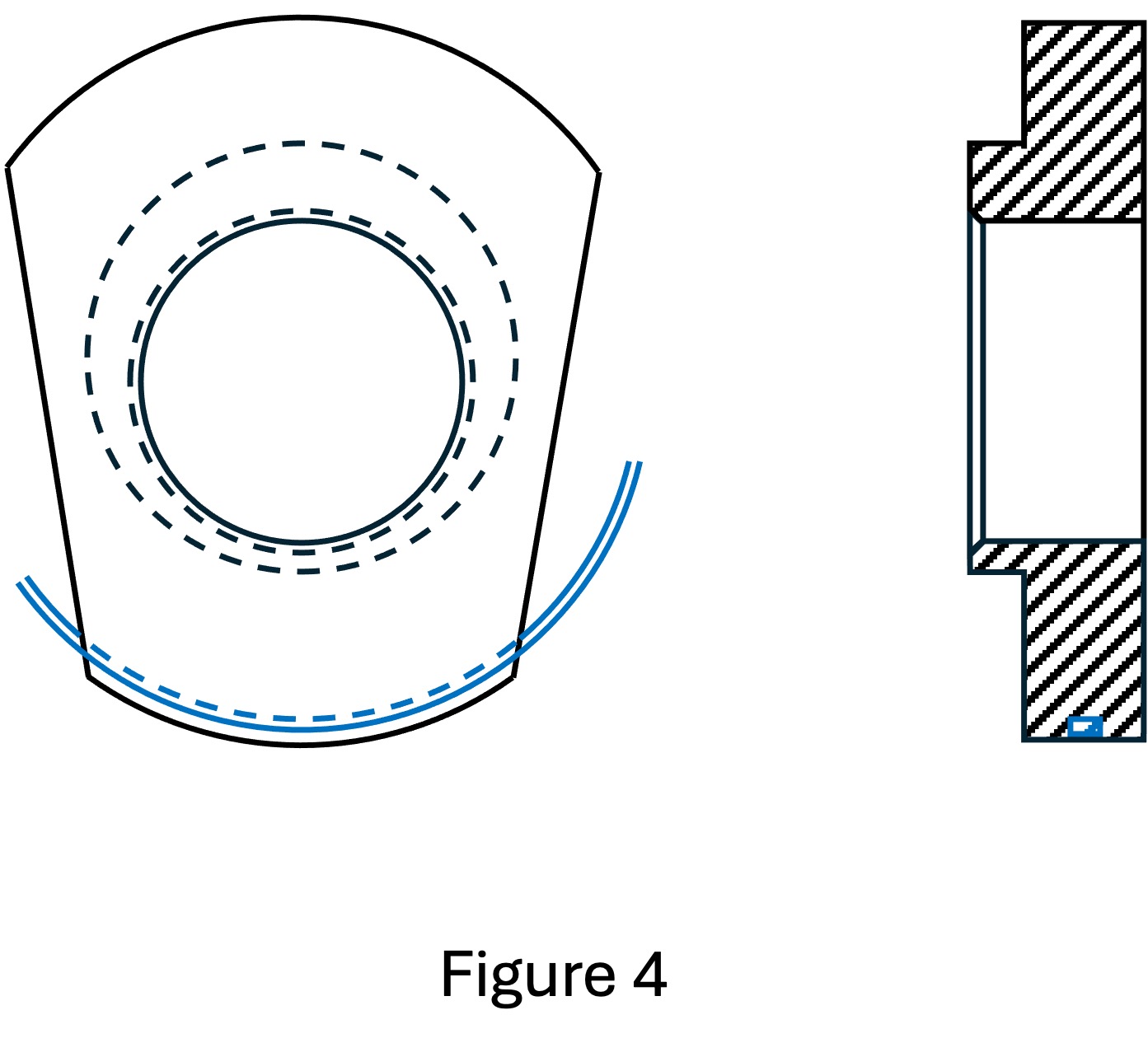

The collet is press-fitted onto the upper part of the balance wheel staff. The fit must be tight enough for the collet to remain perfectly secured to the staff while the watch is running. A wide chamfer is provided beneath the collet, making it easier to fit onto the staff and allowing it to be removed from the staff without damaging the hairspring.

The slit in a conventional collet (Figure 3) allows the collet to be rotated angularly on its staff during adjustment or to correct the beat setting, particularly in watches without a movable stud holder.

The collet is an easy component to manufacture. A simple lathe and a small sensitive drill are all that’s needed to produce it.

The collet is an easy component to manufacture. A few machining operations (turning, drilling, and slot milling) are sufficient, involving a production cycle of only a few seconds.