MOVEMENT LUBRICATION

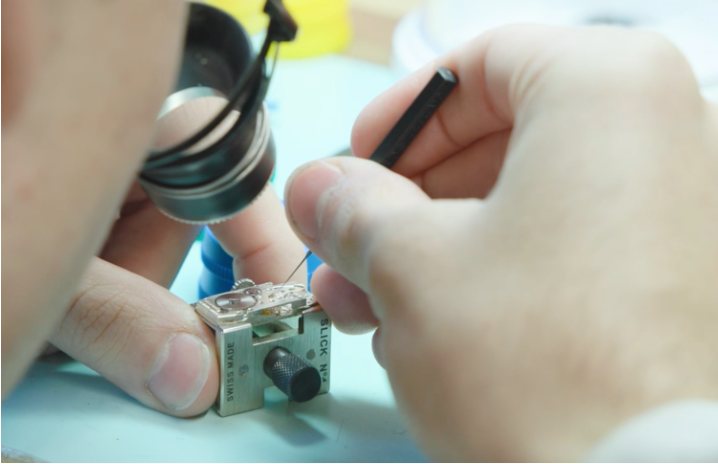

Lubrication of a bearing (manual oiler)

Lubricating the components of a watch movement is an essential operation during assembly and servicing. Its purpose is to reduce friction between moving parts and to limit wear on contact surfaces.

Each friction point, whether pivots, bearings, wheels, or components of specific functions, requires the application of a lubricant suited to its nature and quantity. The watchmaker selects specific oils or greases according to the pressure, relative speed of the components, and expected operating temperature.

Inadequate lubrication, whether through excess, shortage, or incorrect choice of product, compromises the proper functioning of the watch. In the mildest cases, it causes premature wear and more frequent servicing. In extreme cases, it may prevent a movement, even a new one, from starting or running correctly.

The choice of lubricant and mastery of its application form an integral part of watchmaking expertise. These operations are carried out under a microscope, using appropriate tools, to ensure precision and cleanliness.

Types of lubricants

Lubricants used in modern watchmaking are mainly synthetic oils and greases specially formulated to meet the specific demands of mechanical movements. They are classified as follows:

-

Low-viscosity oils, used for high-frequency pivots (escape wheel, balance wheel)

-

High-viscosity oils, for areas with lower speed or higher pressure

-

Greases, applied to points subject to heavier loads or to moving components of functions (correctors, winding mechanisms, etc.)

Each lubricant has a stability temperature, oxidation resistance, and durability that must be compatible with the sealed environment of the watch case.

Application techniques

Lubricant is applied under a microscope, using calibrated oilers or automatic systems in the case of series production. The quantity must be exact: excess can cause oil to migrate to other parts of the movement, while too little leaves surfaces in direct contact.

Lubrication is performed according to a plan based on the movement’s critical points. Certain areas, such as balance staff pivots or pallet stones, require particular attention and specific lubricants.

Historical evolution

In the past, watchmakers used natural oils of animal or vegetable origin. Although effective in the short term, these lubricants oxidised quickly, formed residues, and required frequent maintenance. The advent of synthetic oils from the 1970s onwards radically improved the stability and longevity of lubrication.