MAINSPRING

Figure 1: Exploded view of a barrel (manual winding)

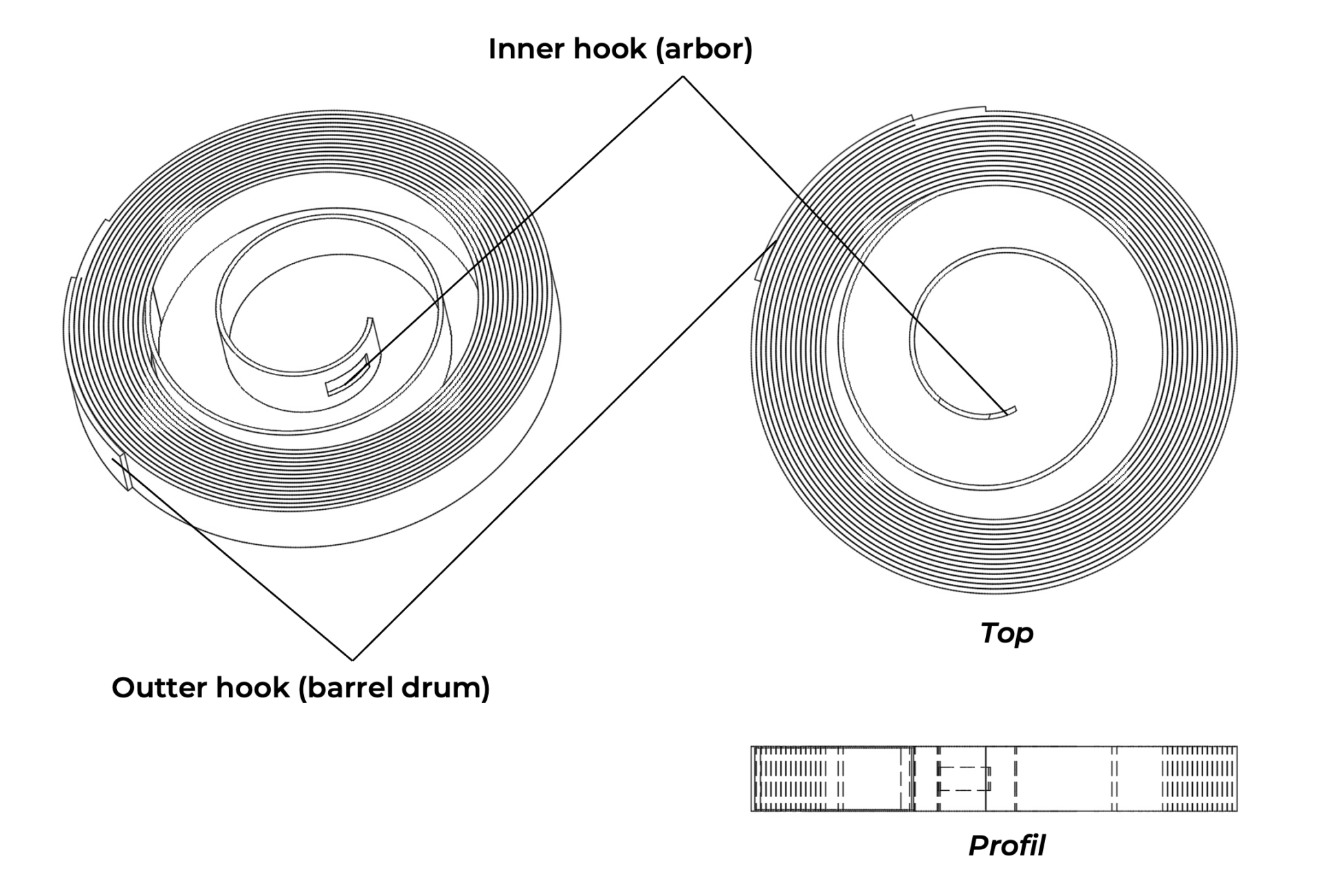

Figure 2: Plan of a mainspring (manual winding)

It is the main component of the barrel, the driving organ of the watch. It consists of a long, rectangular-section steel strip that coils in a spiral around the barrel arbor, inside the barrel drum. Once wound, it is the mainspring that drives the barrel drum in a rotational motion, supplying all the energy needed to power the movement.

When completely unwound and free from any constraint, the mainspring forms a regular spiral in its centre, with the curve of the spiral inverting at the outer end of the spring. This specific shape, fixed during the thermal treatments of the spring, helps provide as constant a torque as possible throughout its unwinding. Or at the very least, to ensure winding curves that are as steady and flat as possible.

The inner end of the mainspring features a rectangular opening that allows it to be secured to the hook on the barrel arbor. At the outer end of the blade, a short section of spring with an inverted curvature is welded to the final coil. This welded section is called the clamp. It allows the outer end of the mainspring to be anchored into the recess machined into the inner wall of the barrel drum.

The length of the mainspring determines the power reserve of the watch.

Its thickness determines the torque it produces, and thus its capacity to drive additional mechanisms (calendars, chronographs, etc.).

The quality of a barrel, therefore, depends primarily on its mainspring. The mainspring must offer optimal efficiency (minimal energy loss for maximum power reserve) and deliver as constant a force as possible throughout its unwinding (for timekeeping accuracy). Careful calculations, which take into account the alloy used, its dimensions, and its thermal treatments, allow for a high-performance, well-adapted barrel.