WINDING PINION

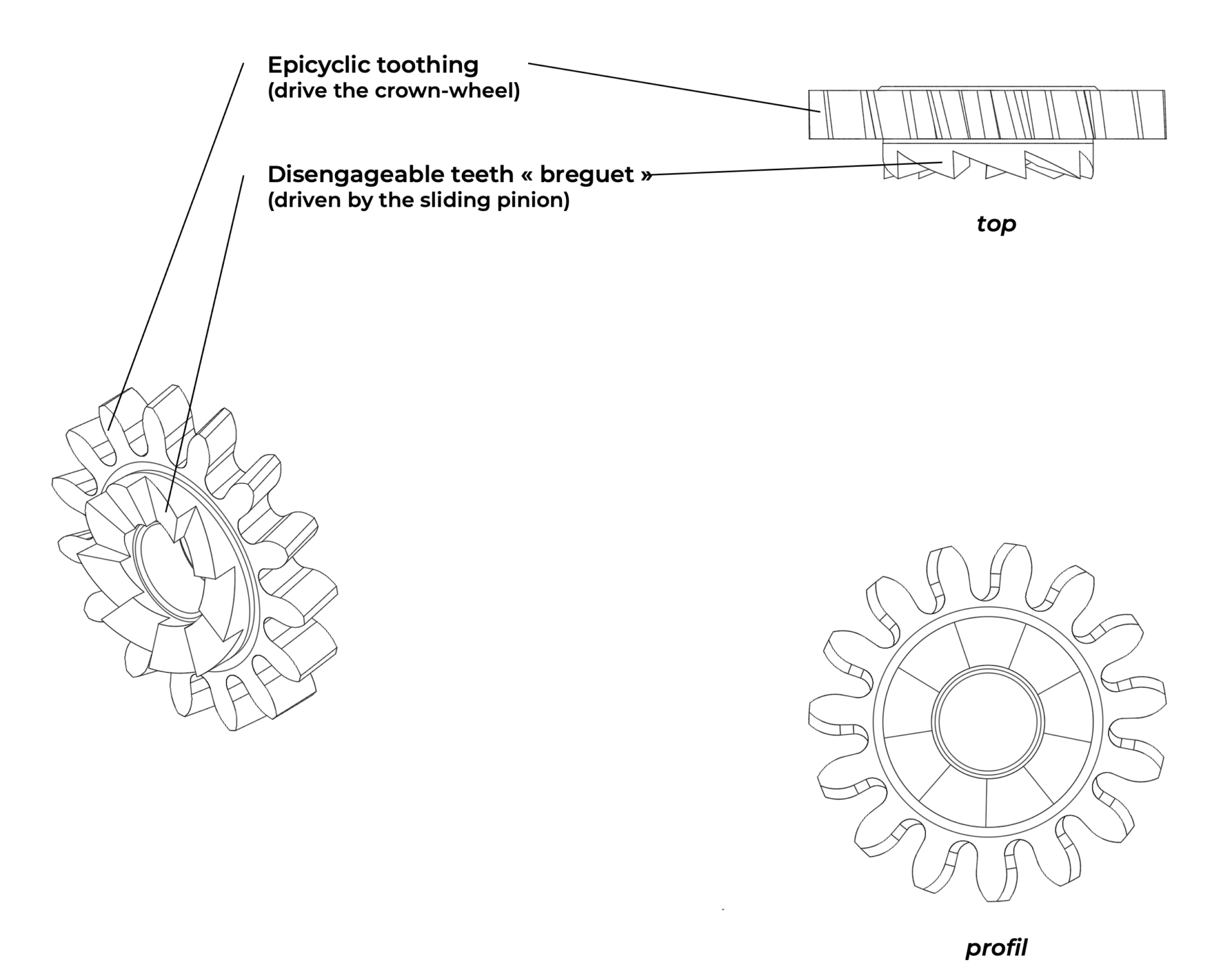

Figure 1: Plan of a winding pinion

Figure 2: Kinematic of the winding mechanism

The winding pinion is made of steel and has two sets of teeth cut perpendicularly. It is a part of the winding mechanism. Its axis is pierced with a hole that allows it to adjust freely to the winding stem.

When the crown (and the winding stem) is pushed (against the case), the yoke places the sliding pinion against the winding pinion. By turning the winding stem, the sliding pinion is driven by the square of the winding stem. In its rotation, the sliding pinion drives the winding pinion with unidirectional teeth of the Brequet system. Due to this tooth profile, the winding pinion is driven only in one direction of the winding stem’s rotation. In the other direction, it disengages, preventing the gear train from turning backwards and putting undue stress (breaking) on the ratchet pawl.

Once driven by the sliding pinion, the winding pinion, with its second set of teeth, drives the crown wheel positioned above or below the barrel bridge on a perpendicular axis.

The invention of the winding pinion can be attributed to Adrien Philippe in 1842 when he patented the first keyless winding mechanism. As the mechanism was not combined with the time-setting mechanism at that time, the winding pinion was directly driven by the winding stem and had a single set of teeth engaging with the crown wheel. It was in 1847 with the invention of the setting lever winding (and time-setting) mechanism by Antoine Le Coultre that the winding pinion took its current form and acquired its characteristic double set of teeth.

A lathe is sufficient to fully manufacture the winding pinion. Turning operations are minimal. Both teeth can be cut on the same lathe using an offset milling cutter and a dividing head. Finishing and polishing can also be done using the lathe.

As with most circular components of small diameter, the automatic lathe is the ideal machine for producing winding pinions regardless of the quantity. Thus, all operations (turning, cutting) can be quickly completed in a single cycle. Regardless of the desired quality, machining a winding pinion using this method will take only a few minutes.