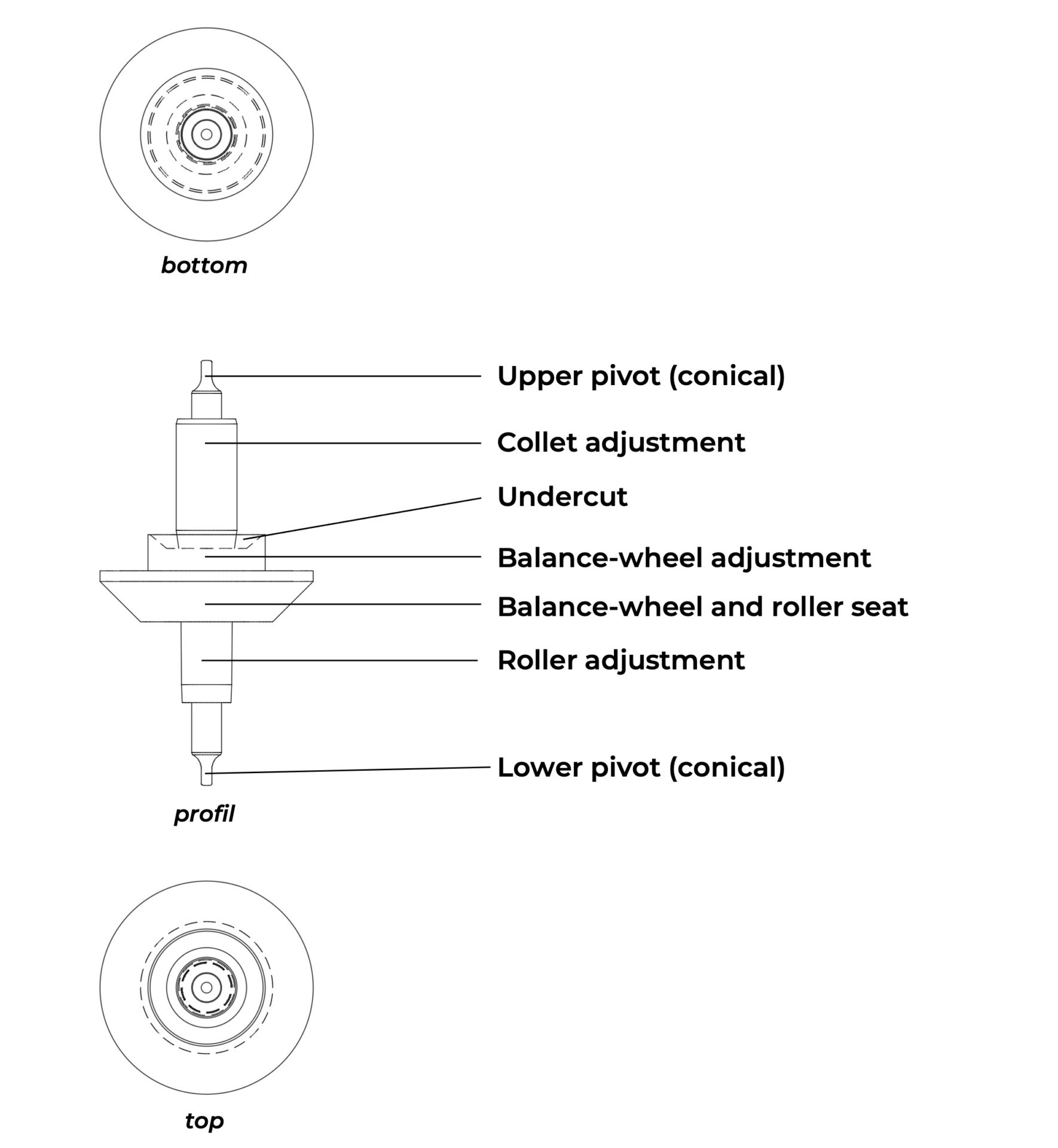

It is a pivoted steel staff that carries all the components of the regulating organ to which it belongs, as well as the final element of the escapement, namely the roller. The balance wheel is riveted to its upper part. Above it, a cylindrical fit receives the collet, which is driven onto it and ensures the connection between the balance wheel staff and the hairspring. Finally, the roller is friction-fitted onto the lower part of the staff.

In order not to disturb the oscillation period of the balance wheel and to minimize friction in its bearings, the pivots of the balance staff are conical and of very small diameter (generally between 0.06 and 0.12 mm).

In the past, breakage of a balance staff pivot was common after an impact. Their small diameter and the large inertia of the balance wheel were the main causes. Modern shock-absorbing bearings have provided a reliable solution to this problem, making pivot breakage a rare occurrence.

The harmful influence of magnetic fields on the regulating organ is well known. Many solutions have already been developed to minimize this problem. Electroforming (UV-LIGA) and deep reactive ion etching (DRIE) technologies have made it possible to manufacture escapement and regulating components from non-magnetic materials (nickel-phosphorus, silicon, etc.). However, these technologies and materials do not allow for the production of a balance staff or for obtaining the mechanical properties required for its proper functioning (strength, hardness, coefficient of friction, etc.). A very recent technology now makes it possible to produce non-magnetic balance wheel staffs made of ceramic and to machine them precisely and in series using femtosecond laser (pulsed laser) technology.

Because of the extremely small dimensions of a balance wheel staff, its artisanal manufacturing requires extensive experience in turning and pivoting. However, it does not require much equipment. A bench lathe and a pivot lathe are sufficient for its production. After turning and burnishing (work-hardening) the various diameters of the staff, a small slot is made with a fine graver just above the balance wheel seat. This slot later allows the balance wheel to be riveted onto the staff (see our video on timing adjustment).

Once the pivots have been turned, they are rolled on the pivot lathe. Rolling is a form of work-hardening: the material is no longer machined, but its surface is compressed and compacted. This operation brings the pivot to its final precise dimension while also increasing its hardness to improve strength and wear resistance, and finally, it reduces surface roughness — thereby lowering the coefficient of friction.

On an industrial scale, balance wheel staffs are produced by automatic lathe. The small dimensions of the balance wheel staff require careful machine adjustment, but turning a balance staff using this method is fast and does not present particular difficulties. The pivots can then be rolled using a machine dedicated to this task. Most rolling machines are not automated and require the intervention of a technician for each staff to be rolled. However, this method saves a considerable amount of time compared to artisanal production and is better suited for series production (repeatability, adherence to tolerances, etc.).

Introduced in 2025, this method makes it possible to produce non-magnetic balance wheel staffs made of ceramic. Unfortunately, the patents protecting the manufacturing process do not currently allow us to detail the steps involved. The principle, however, is to form a ceramic blank through sintering and then machine it using a femtosecond laser (pulsed laser).