CARBON (woven fibres, forged carbon, and nanotubes)

The carbon materials used in watchmaking are predominantly produced synthetically, mainly in the form of composite materials. The exceptional properties of carbon make it a highly valued technical material for the manufacture of external parts (cases, straps, dials) and, occasionally, movement components.

WOVEN CARBON FIBRES

Woven carbon fibres typically refer to a composite material reinforced with carbon fibres. This is the most well-known form of carbon composite, valued for its strength and lightness.

FORGED CARBON

Like woven carbon fibres, forged carbon is a composite in which the resin matrix is reinforced with carbon fibres. However, in the case of forged carbon, the fibres are not woven but cut into segments of a few millimetres and mixed into the matrix with variable density.

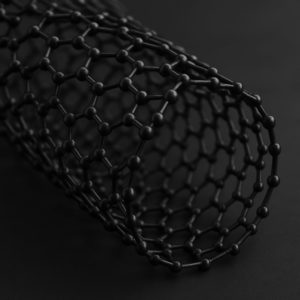

CARBON NANOTUBES (CNTs)

Carbon nanotubes are unique molecular forms of carbon (fullerenes). They consist of one or more sheets of carbon atoms rolled into tubes with diameters ranging from 0.5 to 6 nanometres and lengths of a few micrometres. They are used in composites, and their mechanical properties, electrical conductivity, and thermal conductivity make them particularly appealing for a wide range of technological applications.