INTERMEDIATE WHEEL(S)

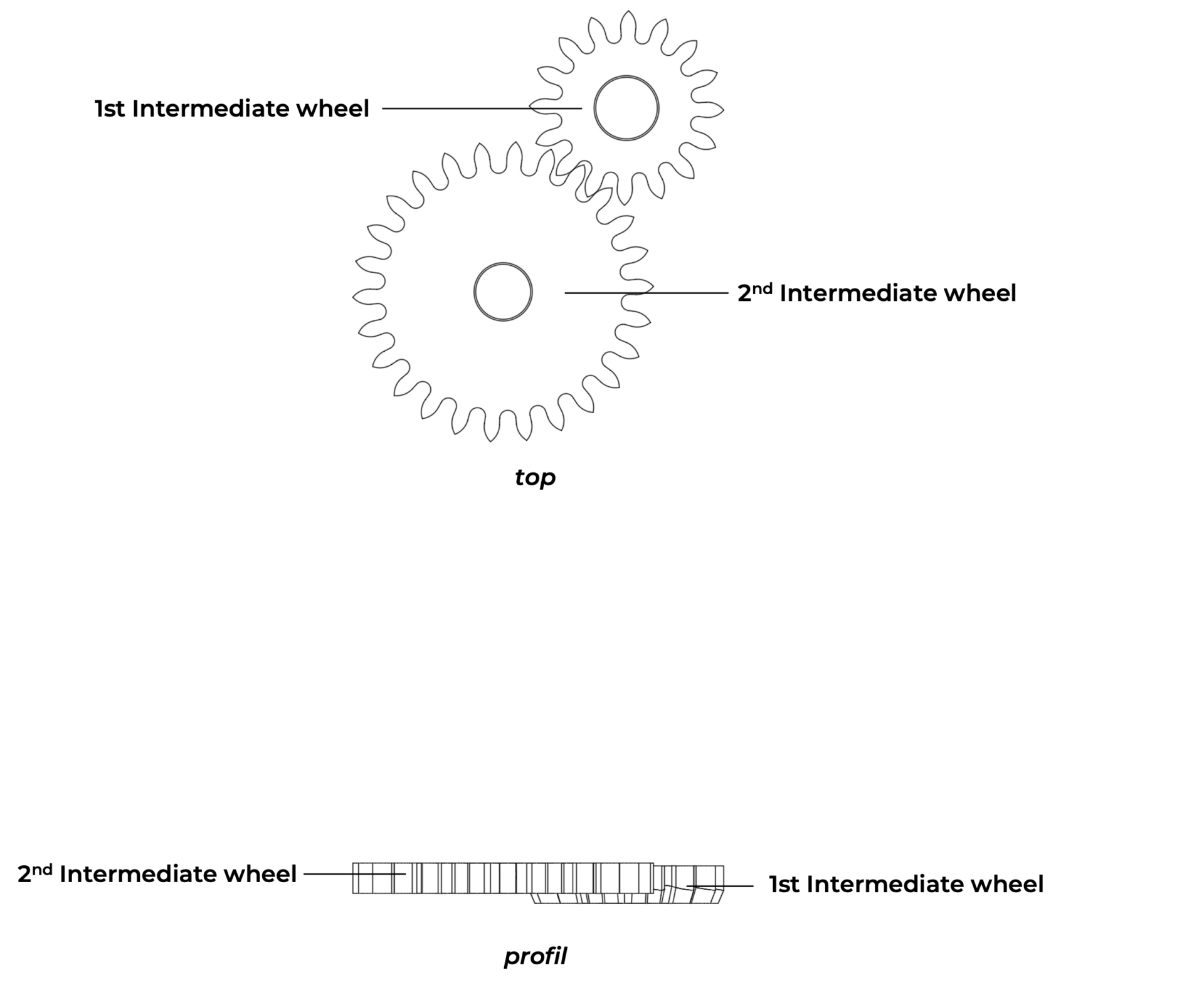

Figure 1: Plan of two combinated intremediate wheels

Figure 2: Kinematic of the time setting mechanism

An intermediate wheel is a simple pinion whose purpose is to transmit the energy from the crown (and thus from the winding stem) to the motion work when the crown is pulled and rotated (during the time-setting). The time-setting mechanism may consist of one or more intermediate wheels. Such wheels are usually made of steel, and their teeth occupy their entire height. The intermediate wheel is pierced at the centre of its axis and pivots on a pivot driven into the mainplate. When the winding stem is pulled, the sliding pinion slides to the end of the winding stem and engages with the first intermediate wheel. A second intermediate wheel often follows, directly driving the plank of the motion work.

Technically, the intermediate wheel is a gear in its simplest form. It is a simple toothed steel cylinder. Gears were already known to the Greeks in the 6th century BC. The earliest known mechanical gears date back to the 4th century BC and appeared in China. With intermediate wheels (and gears in general), watchmakers have simply applied known mechanical principles.

However, it can be considered that the intermediate wheel in the time-setting mechanism as we know it today appeared in the mid-19th century with the successive inventions of Adrien Philippe (pendant winding in 1842) and Antoine Le Coultre (setting lever mechanism in 1847).

A lathe is sufficient to manufacture an entire intermediate wheel. Turning operations are minimal. The teeth can be easily cut on the same lathe using an offset cutter and a dividing head. Finishing and polishing can also be done using the same lathe.

As with most circular components of small diameter, the automatic lathe is the ideal machine for producing intermediate wheels in any quantity. Thus, all operations (turning, cutting) can be quickly performed in a single cycle. Machining an intermediate wheel using this method will take only a few minutes regardless of the desired quality.