ESCAPEMENT TESTER

The escapement tester is a precision instrument used during the final adjusting operations to fine-tune the position of the pallet stones within the fork of the lever. This adjustment is crucial to accurately set the total lock value, which is a vital parameter for the proper functioning of the escapement.

The escapement tester is used for levers in which the pallets are secured with shellac or a heat-sensitive adhesive that becomes pliable when warmed.

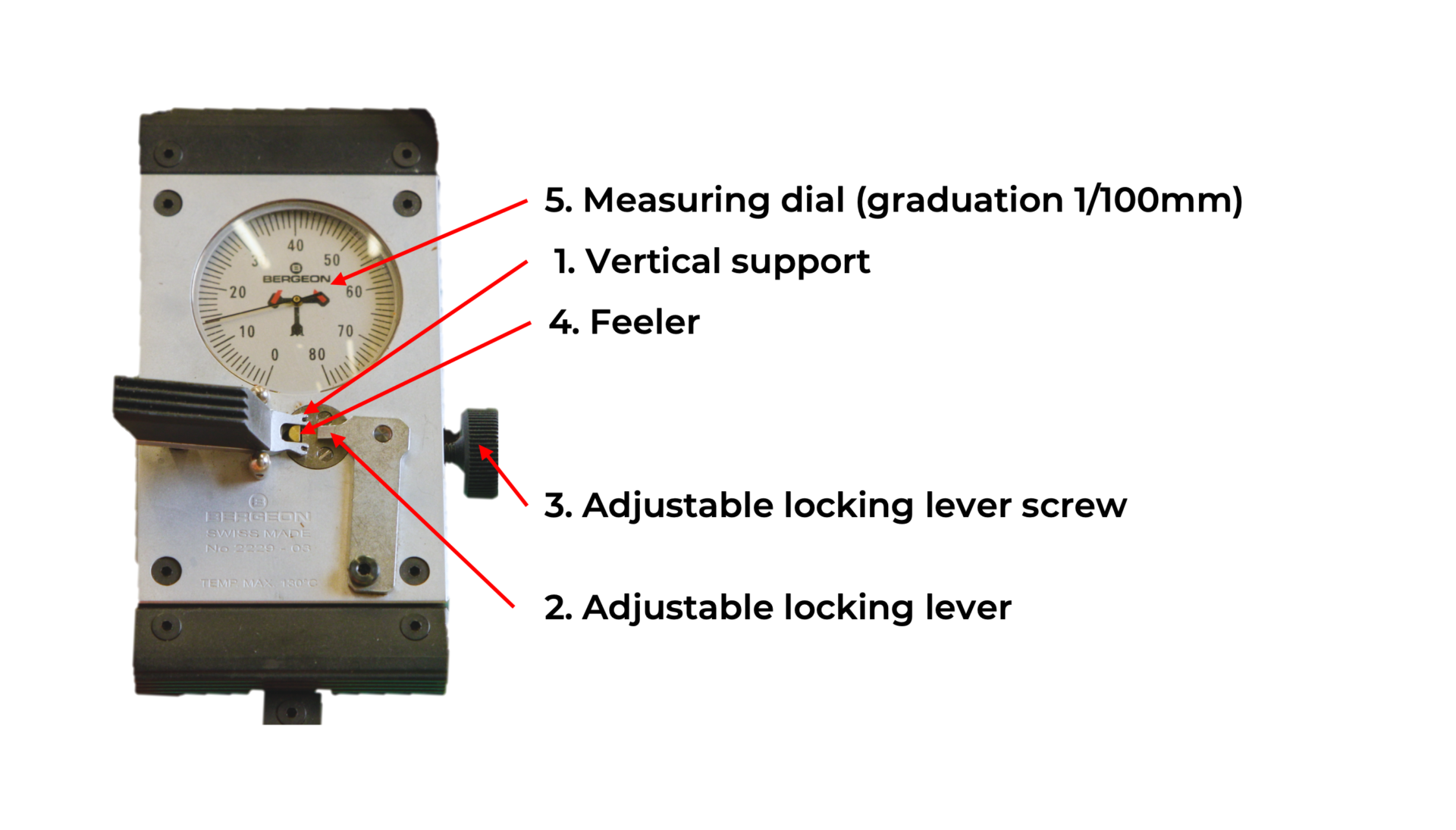

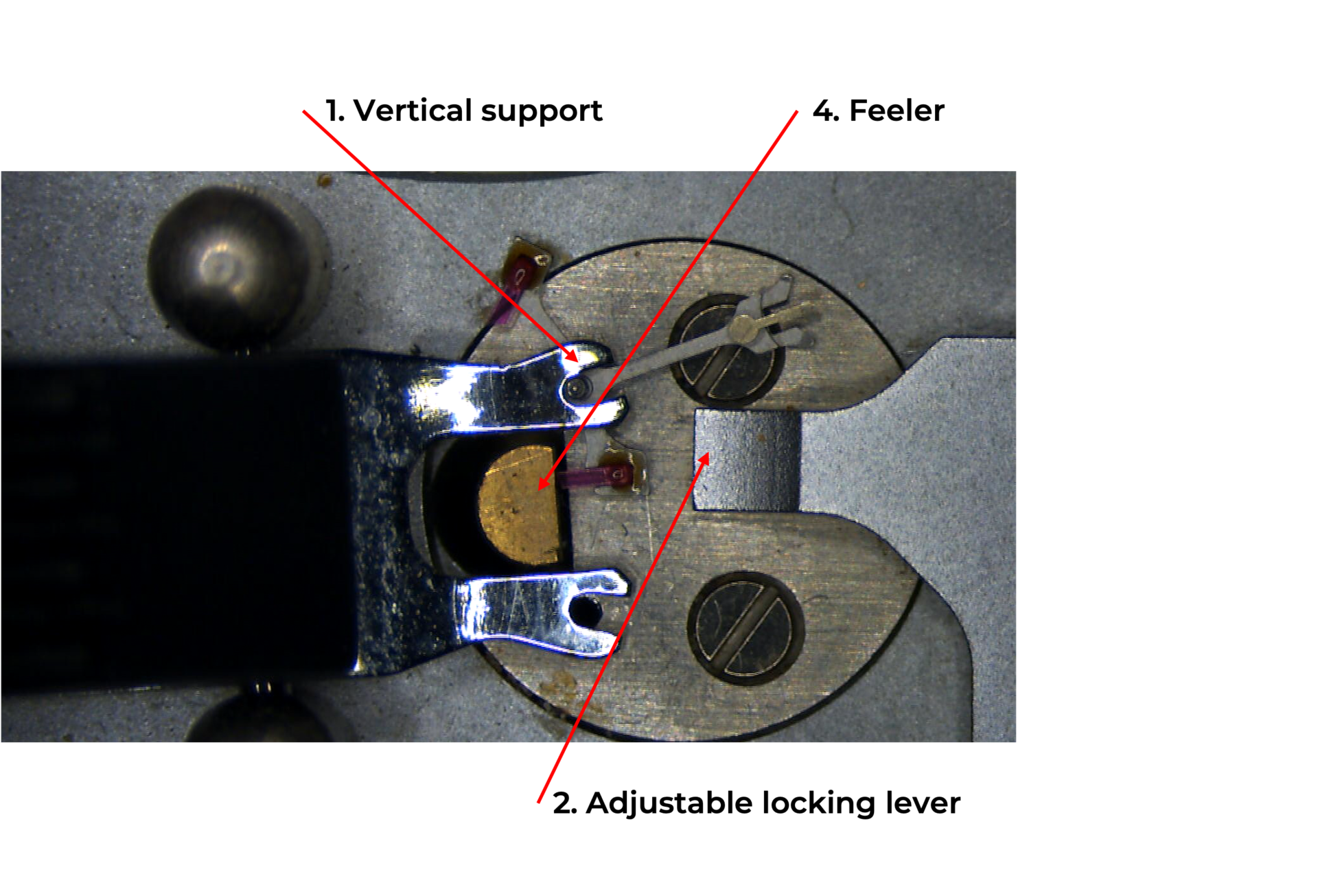

The lever, whose pallet stones require adjustment, is firmly clamped to the frame of the escapement tester by a vertical support (1). The entire device is placed on a heating plate to soften the shellac or adhesive, enabling the repositioning of the pallet stones. An adjustable lever (2), controlled by a screw (3), locks the rear section of the lever’s arm in place.

A feeler spindle (4), held against the impulse face of the pallet by a light spring, ensures constant contact. The feeler is fitted with a small lever connected to a rack, which in turn drives a dial indicator (5), displaying the feeler’s position with a precision of 0.01 mm.

To move a pallet further into its slot, gentle pressure can be applied to the feeéer spindle, which then pushes the pallet into place. To move a pallet outward, a fine-tipped tool is used to push it from the reverse side.

Thanks to the continuous contact of the escapement tester’s feeler with the impulse plane of the pallet, the exact position of the stone can be monitored in real time with exceptional accuracy.