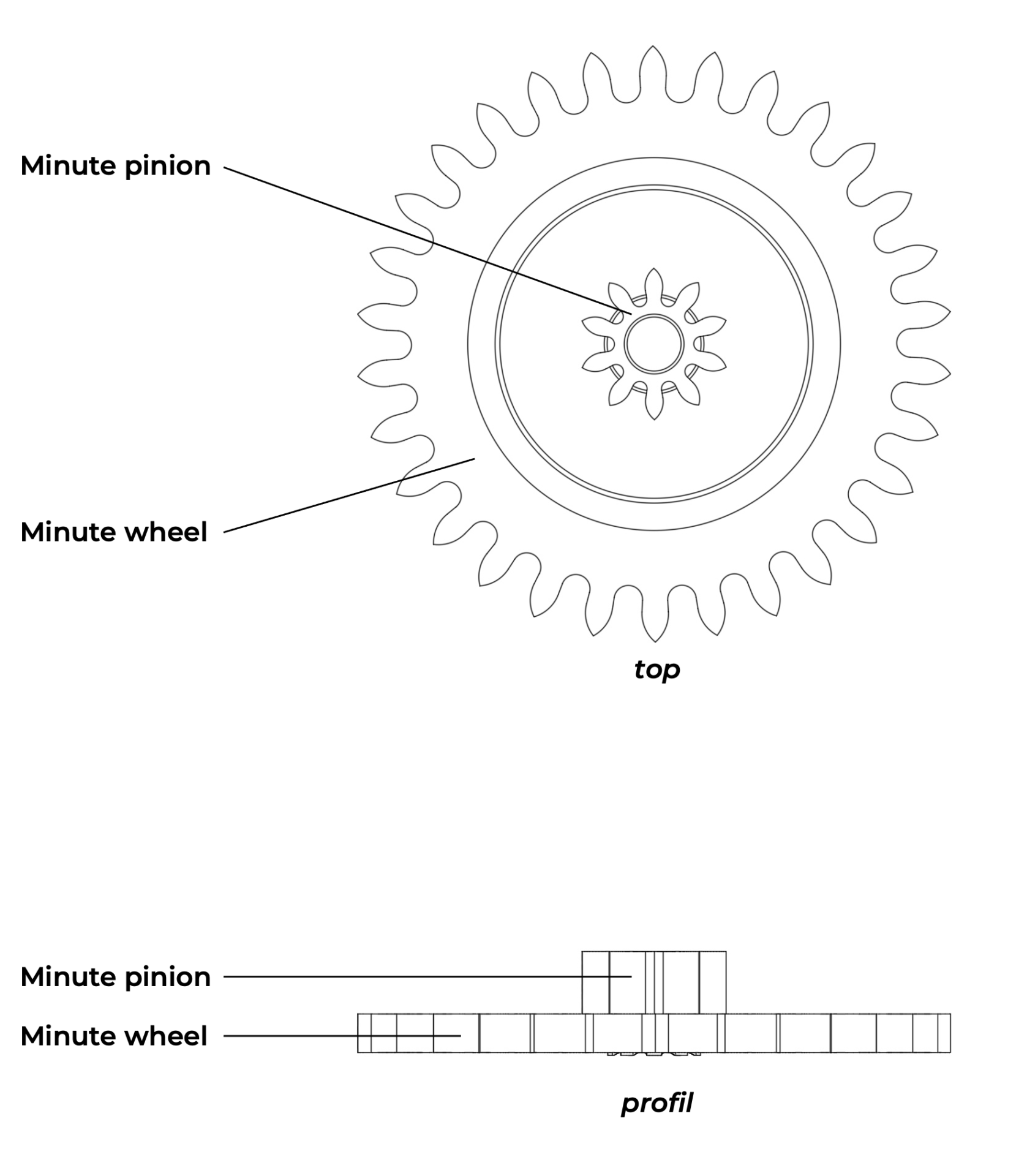

MINUTE WHEEL

The minute wheel consists of a solid brass wheel riveted to a steel pinion. The axis of the assembly is hollow and pivots on a stud driven into the dial side of the mainplate, typically located close to the axis of the minute hand (most often at the centre). The role of the minute wheel is to reduce, through its gear ratio, the rotational speed of the cannon pinion (which carries the minute hand and drives the minute wheel) so that the minute pinion drives the hour wheel (superposed on the cannon pinion and carrying the hour hand) twelve times more slowly (for a 12-hour dial). A thin bridge usually secures the minute wheel and its intermediate wheels, limiting the vertical endshake of the pinion.

The appearance of the minute wheel is intrinsically linked to that of the minute hand, from which it derives. The first minute hands were observed at the end of the 16th century. However, the existence of the minute wheel and its primary function did not depend on the minute being displayed at the centre. The fundamental role of the minute wheel is to increase the rotational speed of the minute hand relative to that of the hour hand. Because of the simplicity with which it fulfils this function, the minute wheel has undergone no significant evolution since its inception.

The minute wheel consists of a solid brass wheel and a steel pinion. In traditional watchmaking, the two components of this assembly can be made on a lathe. Their teeth can also be cut on the lathe using a fly cutter mounted with a dividing plate. A turned shoulder at the base of the pinion allows the wheel plate to be riveted once both components are finished.

The method described here may also be applied, depending on production volumes, at a semi-artisanal level (small series) or on an industrial scale (large-scale production). The automatic lathe is the most appropriate machining solution for producing both the minute wheel plate and the pinion (including the cutting of the teeth). The two components are then decorated, either by hand or by industrial processes, according to the desired finish, before the wheel plate is riveted to its pinion. Producing the wheel plate by stamping would offer little advantage, since the cutting of the teeth would, in any case, require a subsequent operation on a gear-cutting machine.