HOUR-WHEEL

The hour wheel is generally made of brass for two reasons. Firstly, it is driven by the minute wheel pinion, which is made of steel. Secondly, it pivots in direct friction on the steel cannon pinion. Considering that the steel-brass combination is optimal for minimizing friction, the choice of this material for manufacturing the hour wheel seems obvious.

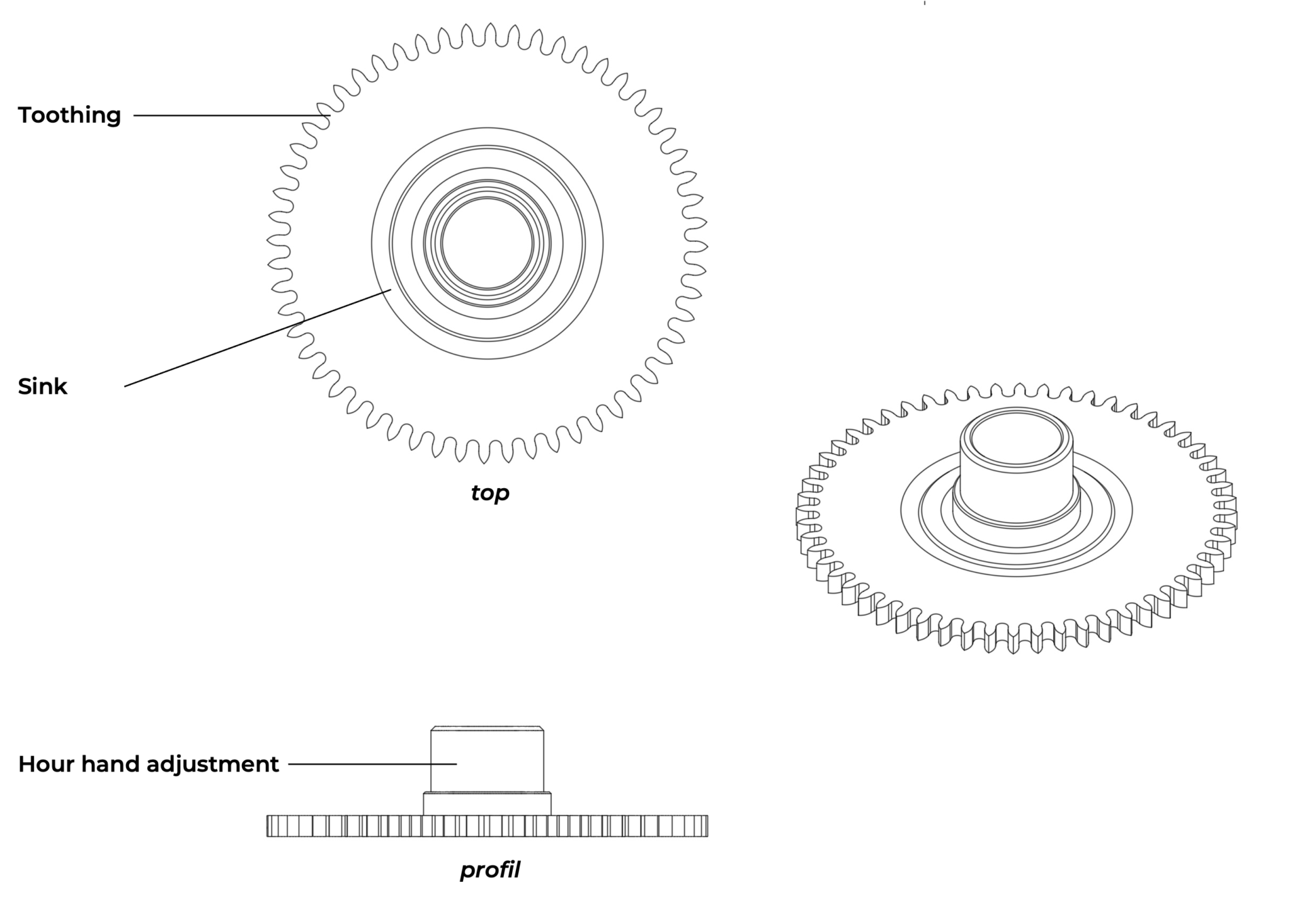

Technically, the hour wheel is a simple piece. As a base, it has a thin, large-diameter wheel plate, on the periphery of which the teeth are cut. In the centre of this base rises a tall tube (the cannon pinion, also referred to as the hour wheel). At the top of the hour wheel’s cannon, there is a bearing to accommodate the hour hand.

The hour wheel is driven by the minute wheel pinion, and it completes 1 revolution every 12 hours when the dial displays twelve hours.

The emergence of the hour wheel is connected to that of the motion works, with Daniel Quare credited as its inventor in the mid-17th century. Before both hands were concentrically displayed at the centre of the movement, and the hour wheel simply had no reason to exist. As simple in function as in construction, the hour wheel has undergone no major changes in four centuries!

The hour wheel is easy to manufacture regardless of the method used. Only a few parts (teeth, cannon pinion, hand-bearing) need to be turned. A simple conventional lathe is more than sufficient to produce them. The tooth profile can be cut on the same lathe using a universal dividing tool or later using a gear-cutting machine.

Due to the circular frictions, it undergoes (with the cannon pinion, under the dial), the cannon wheel is generally decorated with a simple circular satin finish, which is easy and quick to achieve (buff stick/lathe).

The hour wheel is easy to manufacture regardless of the method used. Only a few parts (teeth, cannon-pinion, hand-bearing) need to be turned. For industrial production, the automatic lathe is once again the ideal tool. The tooth cutting can be done on this machine, and only a few simple steps of decoration will be carried out after the component has been machined.