REGULATING ORGAN (balance wheel – hairspring system)

Definition

The regulating organ is the oscillating device that sets the rate of a timepiece. In portable watches (pocket or wrist), the regulating organ is generally the balance wheel and hairspring assembly, which forms a harmonic oscillator whose period regularity determines the watch’s accuracy. It converts the energy stored in the mainspring into a succession of regular oscillations, thereby governing the regularity of timekeeping.

Different regulating organs

| Type of timekeeping instrument | Regulating organ | Frequency | Accuracy |

|---|---|---|---|

| Clocks | Pendulum | 0.5–1 Hz | – |

| Mechanical watches / clocks | Balance-spring | 2.5–5 Hz | approx. 5-10 s/day |

| Electronic watches | Tuning fork | 300–720 Hz | approx. 5-10 s/month |

| Electronic watches | Quartz crystal | 32,000 Hz | approx. 1 s/month |

| Atomic clocks | Atoms (various types) | 429,228,004,229,873.2 Hz | approx. 1 s/13 billion years |

The balance wheel–hairspring system

Description and components

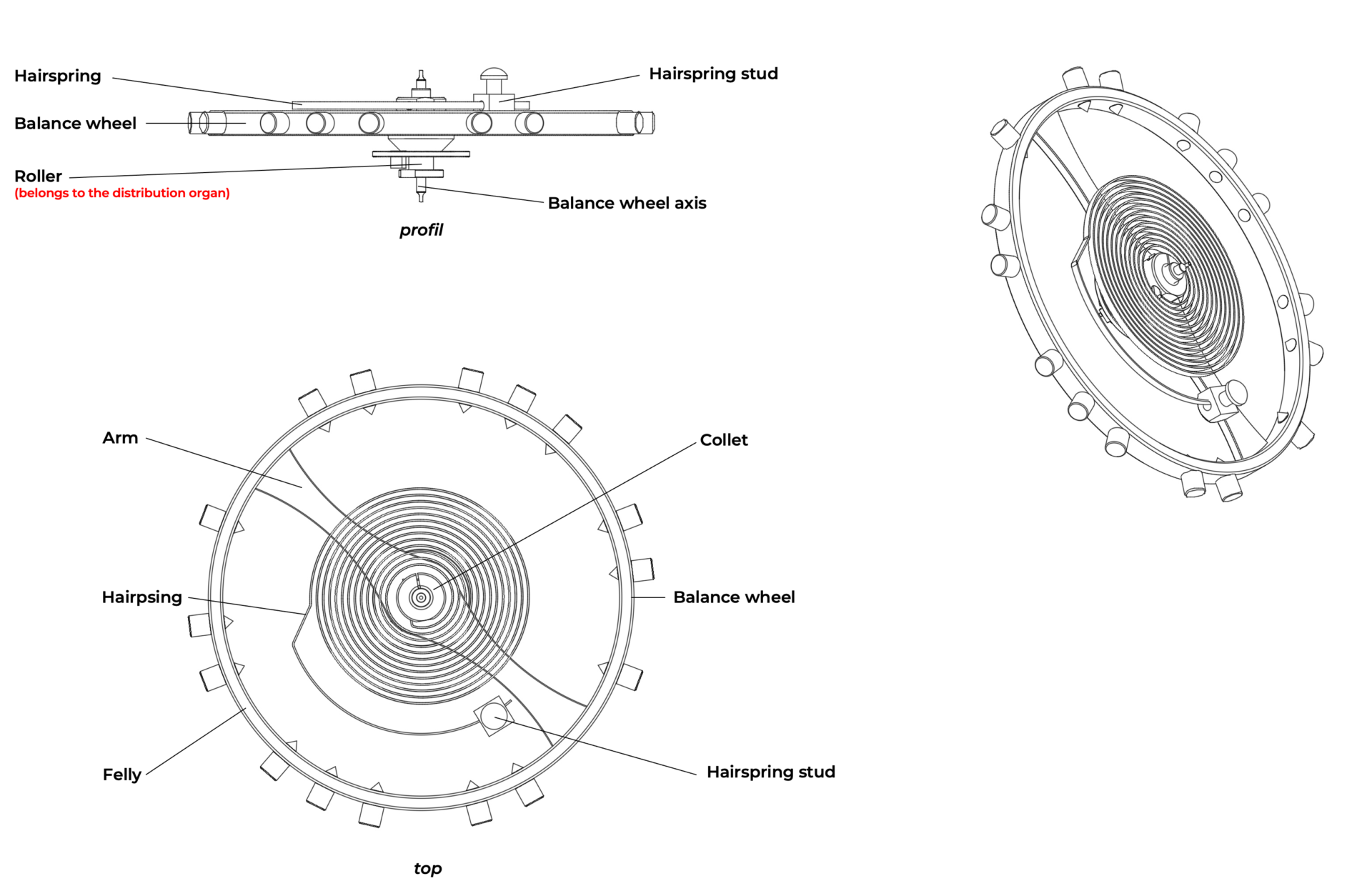

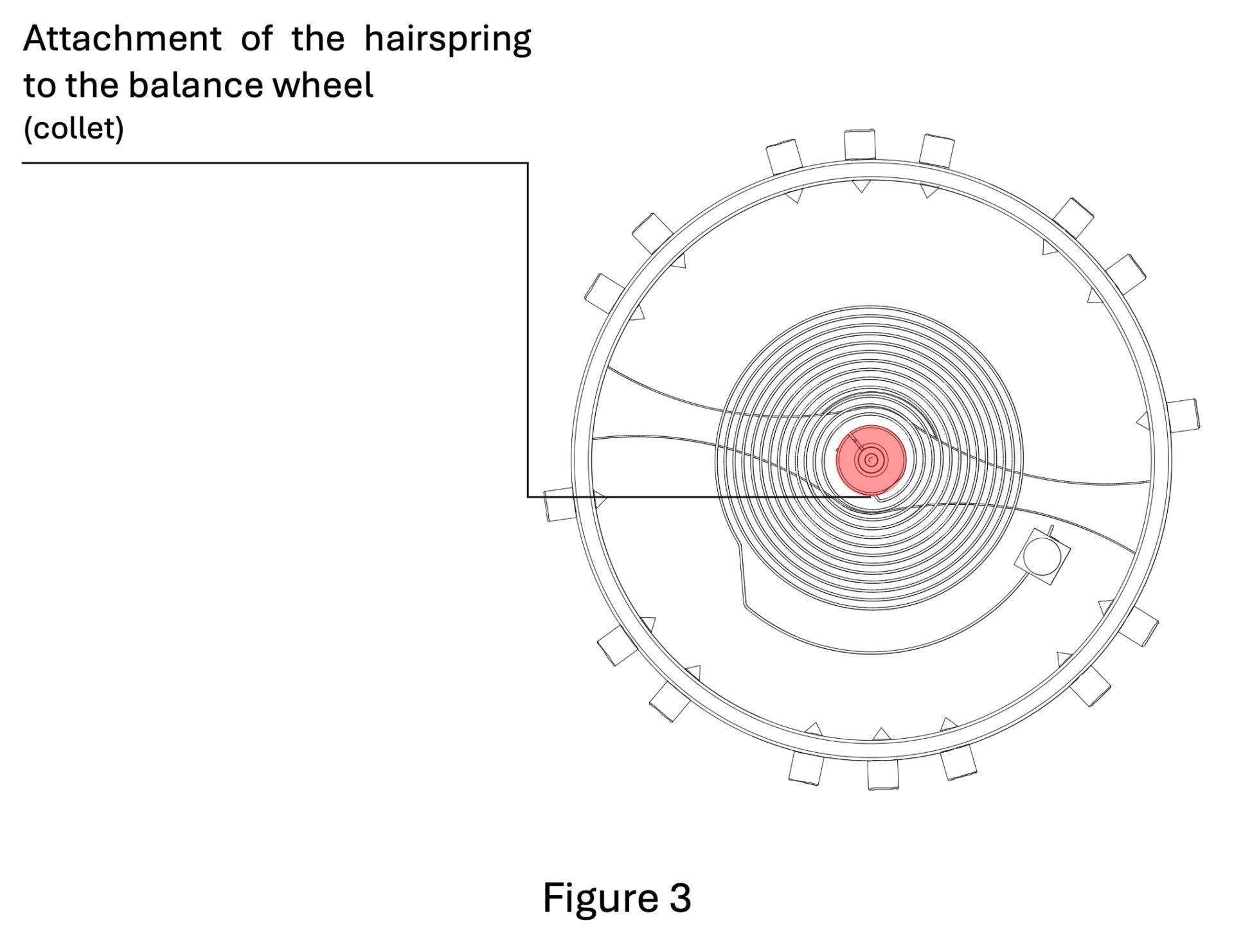

The regulating organ of mechanical watches consists mainly of an inertia wheel called the balance wheel and a spring in the form of an Archimedean spiral called the hairspring. The balance wheel is riveted onto its staff. On this same staff, the inner end of the hairspring is fixed by means of the collet (Figures 2 & 3).

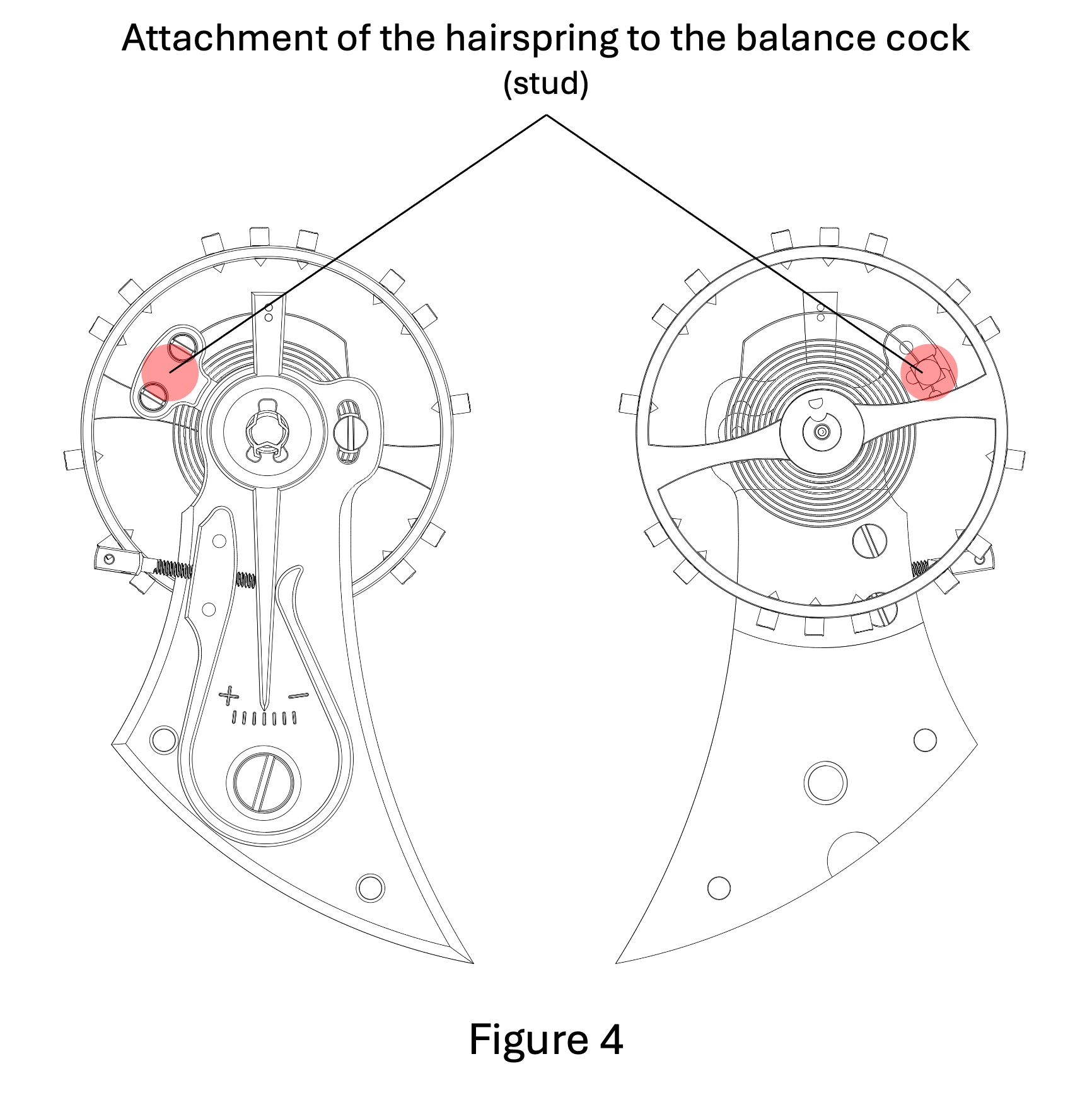

The outer end of the hairspring is fixed to the balance cock by means of the stud (Figures 2 & 4).

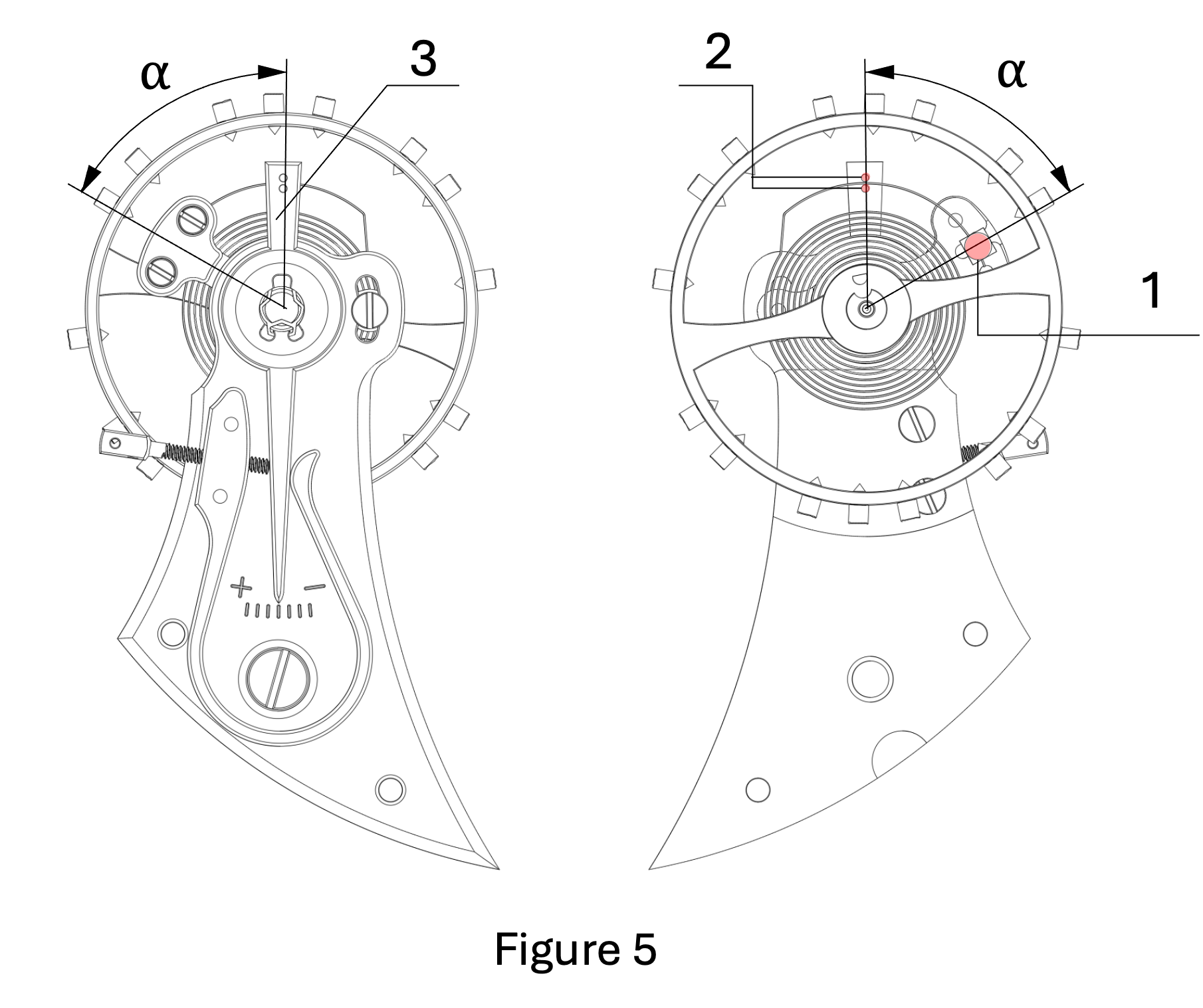

At an angle α generally between 60° and 70° from the stud (Figure 5, point 1), the terminal curve of the hairspring passes between the two regulator pins (Figure 5, point 2). The regulator pins are press-fitted into the regulator index (Figure 5, point 3), which pivots with slight friction concentrically to the balance wheel axis.

Important:

The presence or construction of the various components of the regulating organ may vary from one movement to another (e.g., optional presence of a regulator index or a movable stud holder).

Balance–hairspring motions

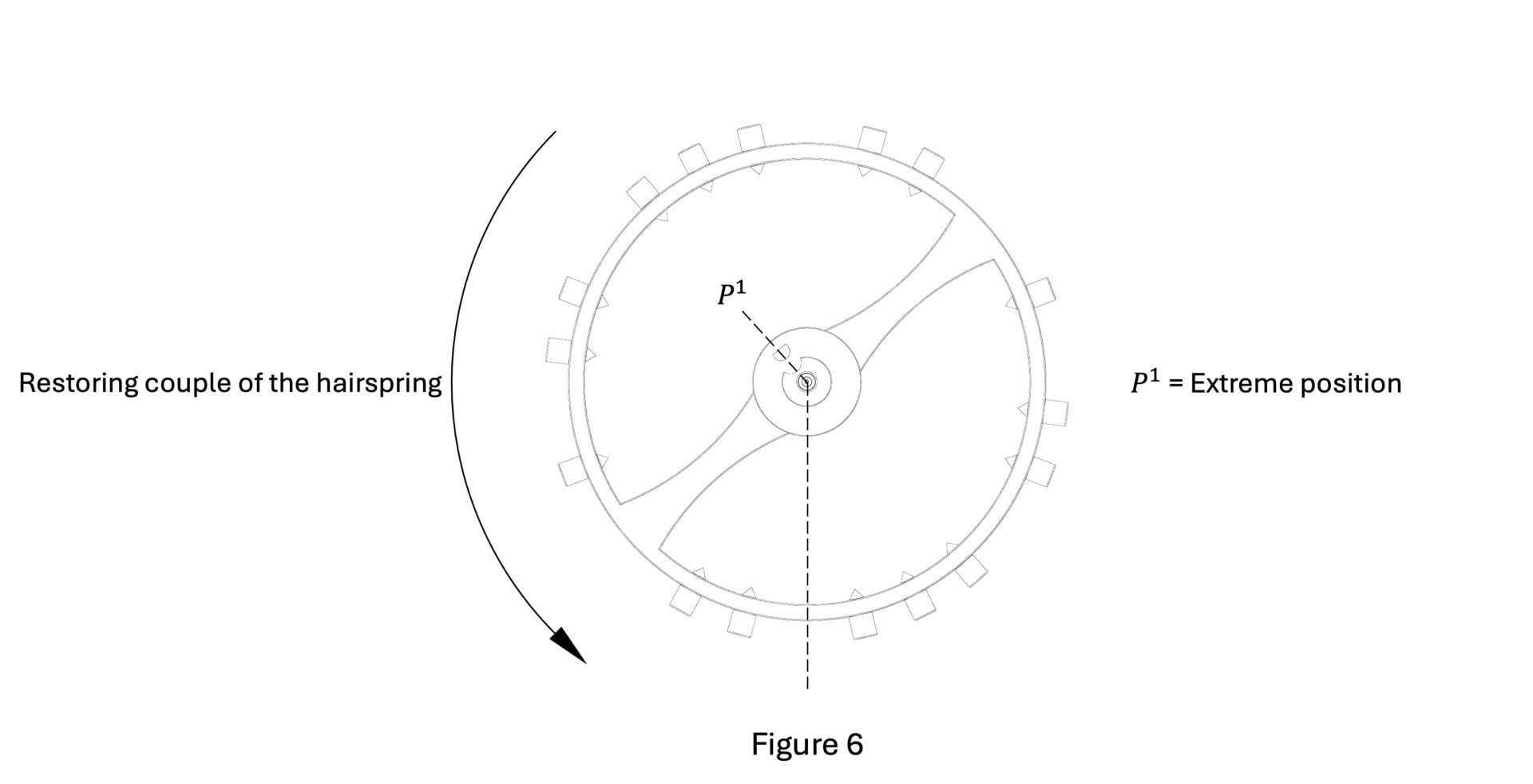

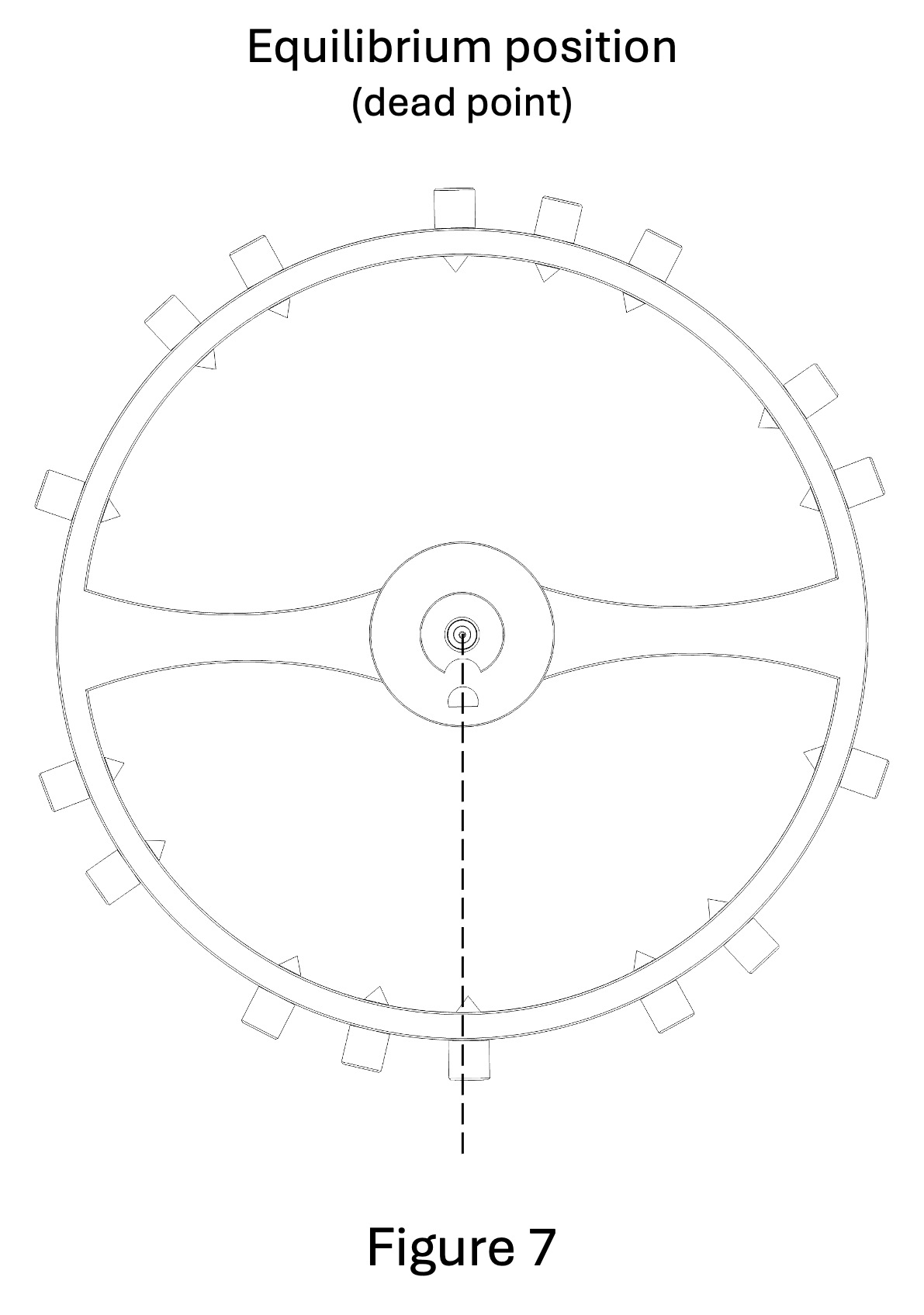

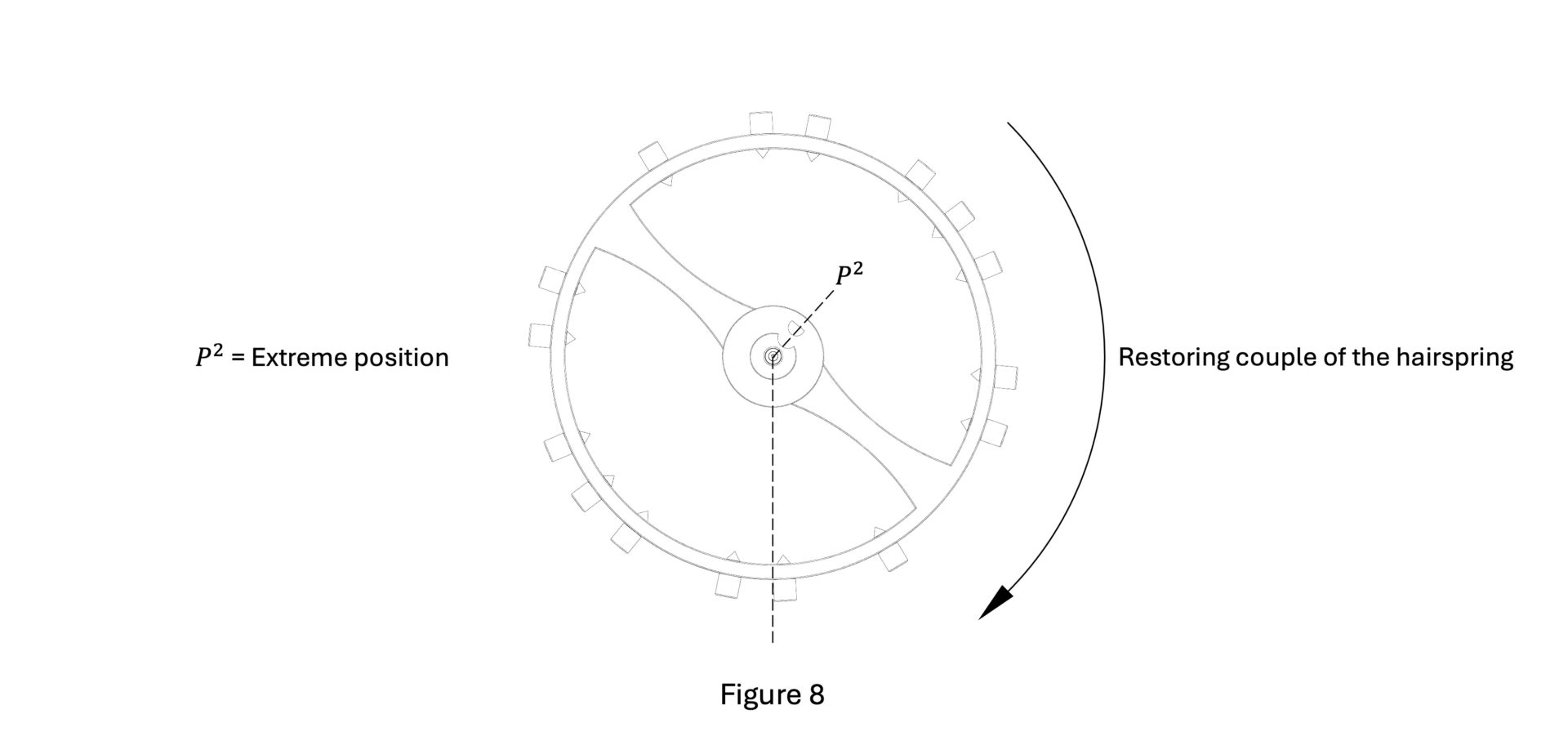

During the operation of the watch, the hairspring oscillates concentrically about its axis on either side of its equilibrium position, also called the equilibrium position or “dead point” (Figure 7). When the balance wheel is pushed beyond its equilibrium position (during an impulse; see escapement), the hairspring is wound.

When the impulse is delivered in one direction, the spring is tensioned in extension (Figure 6), and when the impulse is delivered in the other direction, the spring is tensioned in contraction (Figure 8). In both cases, a restoring torque (elastic torque) is created that brings the balance wheel back to its equilibrium position (dead point) (Figures 6 to 8).

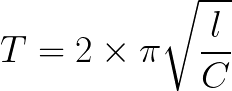

T = Period (s)

I = Moment of inertia of the balance about its axis (kg·m²)

C = Elastic torque (stiffness) of the hairspring (N·m/rad)