SECOND WHEEL

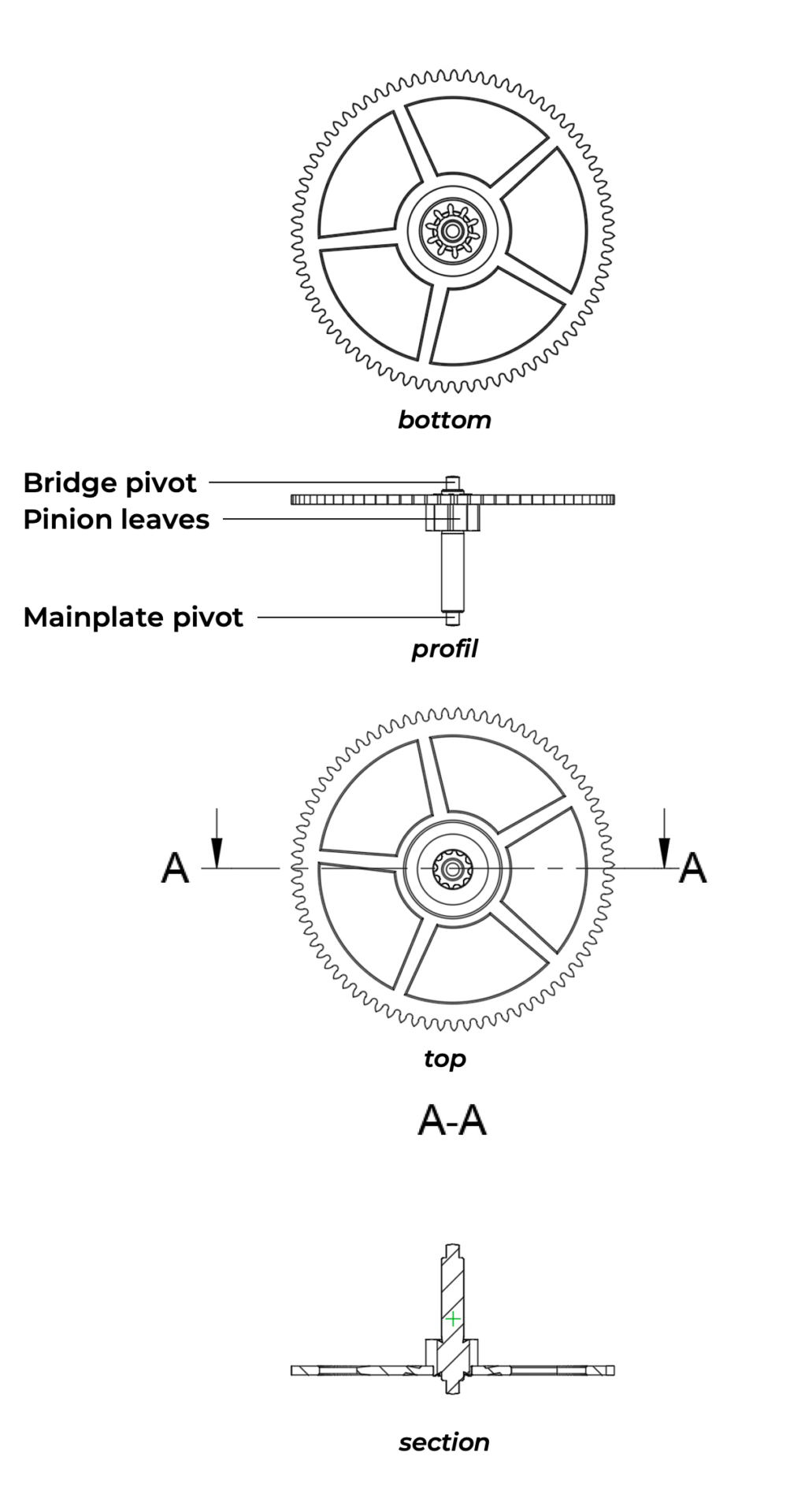

Figure 1: Plan of an assembled second wheel

The second wheel belongs to the counting and transmission organ. It is an essential element of the gear train. Positioned between the centre wheel, which receives energy directly from the barrel, and the third wheel, to which it transmits this energy, it plays the role of an intermediate relay and speed reducer, ensuring that the centre wheel rotates more slowly than the third wheel, which is closer to the regulating organ.

Positioning and rotational speed

As it does not carry a hand, the second wheel is not required to rotate at a specific speed, unlike the centre wheel (1 rev./hour) or the third wheel (1 rev./minute when carrying a seconds hand). Similarly, its positioning is flexible, allowing it to be defined during the development of the movement to optimise space within the calibre and, to some extent, the efficiency of the gear train.

Its two principal functions are:

-

Transmission of energy: It receives the driving energy from the centre wheel and transmits it to the third pinion.

-

Reduction of gear ratio: It contributes to the overall gear ratio of the gear train, ensuring that, in line with the frequency of the regulating organ, the centre wheel and the third wheel rotate at the correct speeds for timekeeping (see counting and transmission organ calculations).

Components

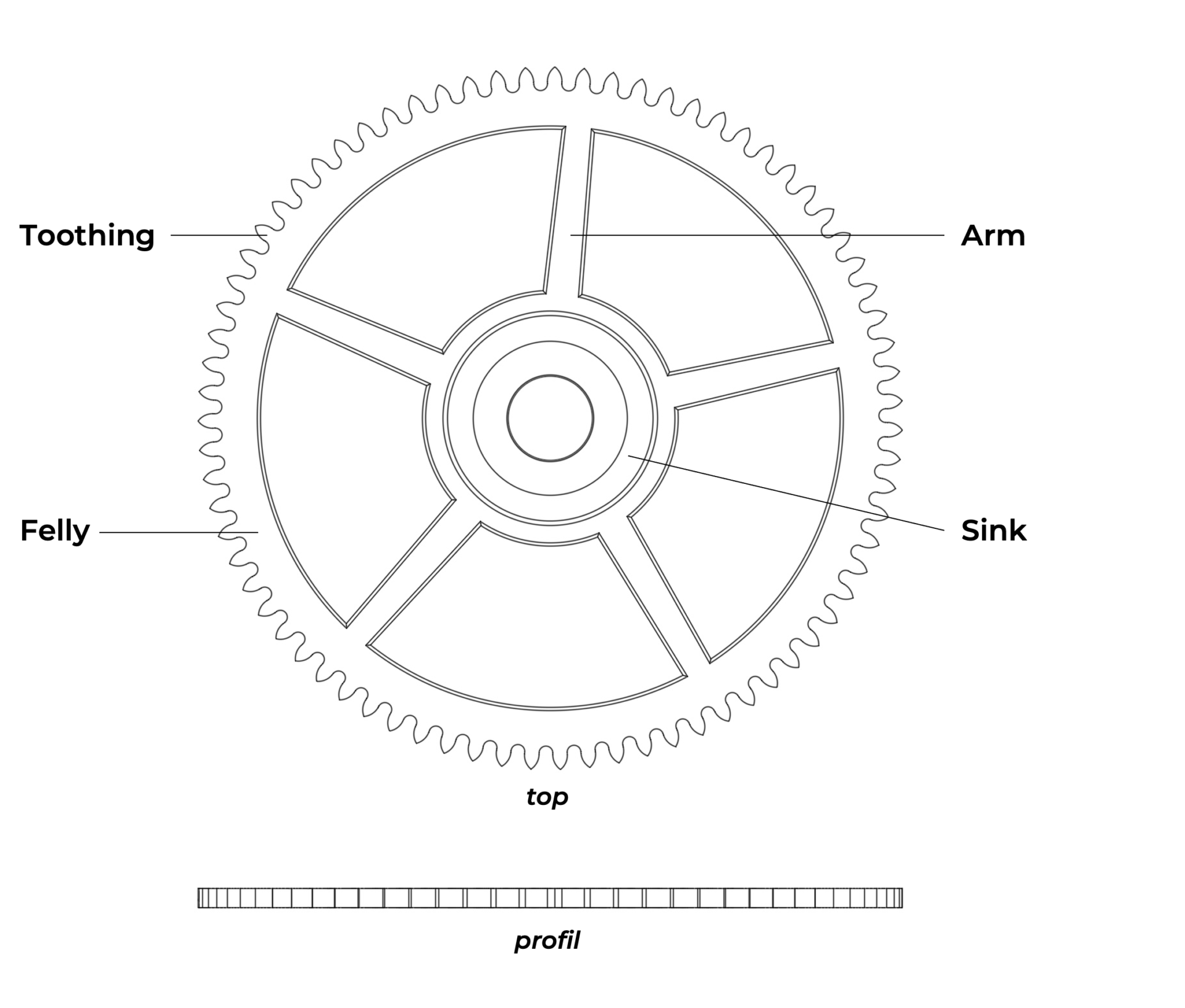

Like the other wheels of the gear train, the second wheel is composed of two parts:

-

Wheel: Driving the pinion of the third wheel (driven).

-

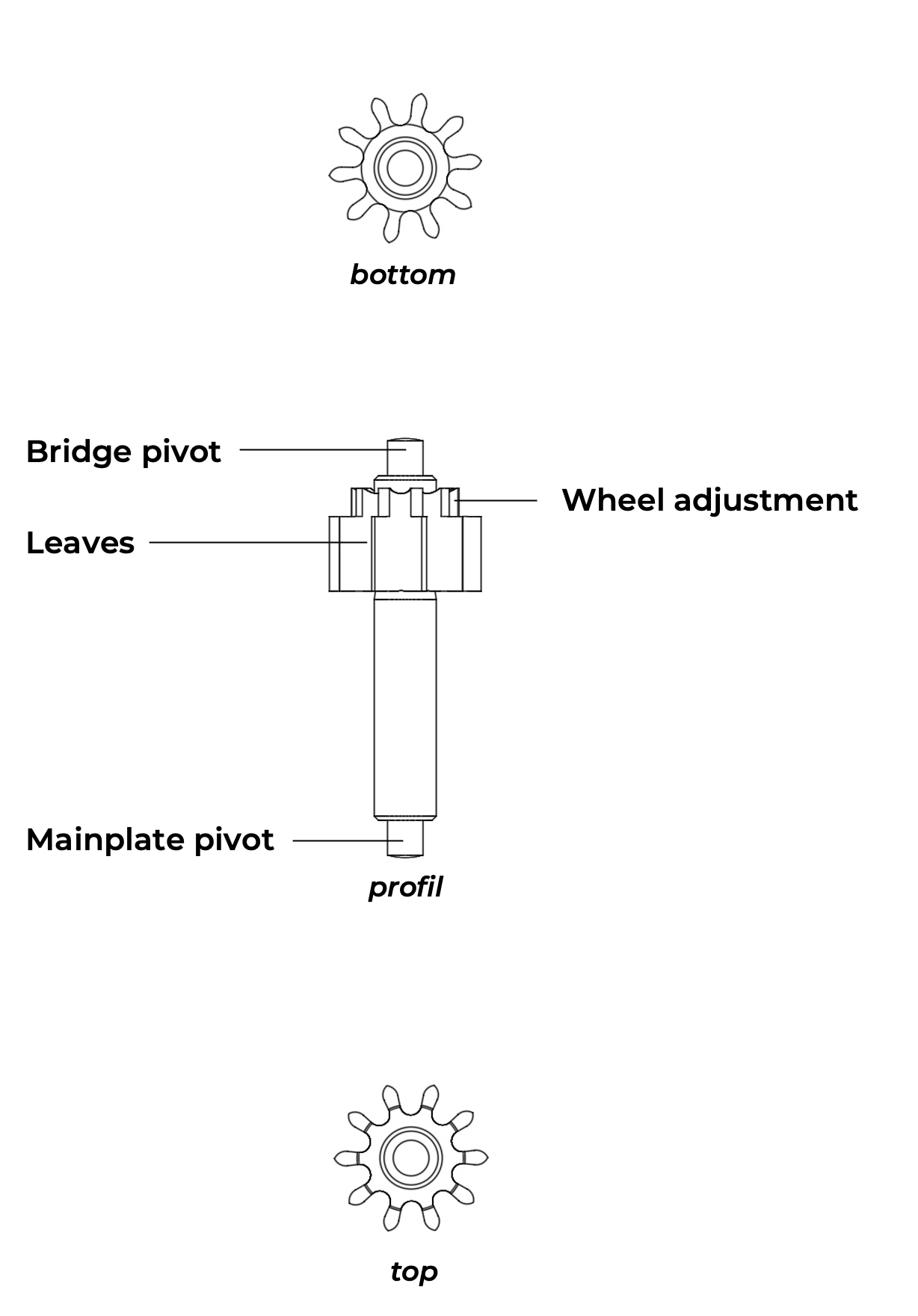

Pinion: Forming the axis of the wheel. It is driven by the centre wheel (driving).

Materials

Traditionally, the second wheel is made of gilded brass. The pinion is of hardened, mirror-polished steel to enhance mechanical resistance. The pivots are burnished (surface work-hardened). They run in synthetic jewels (rubies) and are lubricated to minimise friction and wear.

The pairing of a brass wheel with a steel pinion is optimal for reducing friction in the gear trains of a movement. This construction applies to most multiplicative or reducing trains in a watch (gear train, setting train, etc.).

Technical features

The wheel blank is firmly riveted to the pinion, creating a solid and inseparable assembly.

The toothing ratio of the second wheel, and of the finishing train as a whole, is calculated to ensure that the centre wheel completes one revolution in sixty minutes. It is an essential condition for the direct driving of the cannon pinion and the minute hand and, by further reduction, the hour hand (see counting and transmission organ calculations).