MOTOR ORGAN

- Definition and different types of motor organs

- Description & components

- Functioning

- Motor organ calculations

Definition

The power source of a timekeeping device provides the energy required for its proper functioning.

Different types of power sources

Weight / gravity – Weight-driven clocks

Spring / barrel – Wristwatches, pendulum clocks, alarm clocks

Battery / electrical power – Electric, electronic, and atomic watches and clocks

Weight-driven motor:

The driving weight of a clock is attached to the end of a cord or chain wound around a cylinder fitted with a gear. Through the force of gravity, the weight descends and drives the cylinder and its gear in a rotational motion. This rudimentary system produces a perfectly constant torque. The power reserve depends on the length of the cord or chain to which the weight is attached (and its available drop distance). Once the cord or chain is fully unwound, the clock stops. A crank or key mechanism, together with a ratchet, allows the cord to be wound back around the cylinder, raising the weight once more. It is from this type of mechanism that the expression “winding a watch” originates.

Unlike a barrel or battery, a weight-driven system does not store energy.

The barrel:

The barrel is a power source system found in some small clocks and pendulums, as well as in all portable watches (pocket watches and wristwatches). It consists of a spring wound inside a cylinder that stores energy accumulated during manual or automatic winding, and gradually releases it to drive the movement. This is the type of power source we will examine in detail in this chapter.

The Battery:

In electronic watches (tuning fork, quartz, etc.), energy (in electrical form) is stored in the battery, which powers the movement (oscillator, stepper motor, display). An external electrical supply (as used in electric or atomic clocks) does not store energy and is thus suited to fixed instruments only.

Description

The complete motor organ of a mechanical watch is called the barrel. The barrel consists of four components:

– Barrel drum: A cylindrical component housing the mainspring. Around the outer edge of the drum is a toothed rim (or ring gear) that meshes with the centre pinion, transmitting energy from the barrel to the rest of the gear train.

– Mainspring: A long, rectangular-sectioned steel blade. When wound (manually or automatically), it stores energy and then gradually releases it to power the watch.

– Barrel arbor: The central axis of the barrel around which the mainspring coils.

– Drum cover: Once the mainspring and barrel arbor are properly positioned inside the drum, the cover snaps into place, sealing the barrel and protecting the spring from dust.

Barrel assembly

The first step is inserting the mainspring into the barrel drum. When new, mainsprings are delivered fully coiled and tensioned, encircled by an aluminium retaining ring. To install, position the mainspring in the centre of the drum, press it to the bottom, and remove the aluminium ring. To reinstall a relaxed mainspring, it must be rewound and tensioned using a mainspring winder, which is also used to insert it into the barrel. Modern mainsprings are self-lubricating and require no additional greasing.

After lightly lubricating the pivots of the barrel arbor to allow it to rotate freely inside the drum, the arbor can be placed centrally in the barrel, ensuring it passes through the inner coil of the mainspring. Once properly positioned, the innermost coil must hook onto the arbor’s collet.

After confirming that both arbor and the full length of the spring are seated correctly at the base of the drum, the assembly is closed by snapping the barrel cover into place. This is done using a dovetail (or eagle-claw) type fit to securely fasten the cover.

Winding Phase

The ratchet wheel is the final component of the winding mechanism and is fitted onto the barrel arbor, to which it is connected via a square fitting. This square fitting allows the ratchet wheel to drive the barrel arbor in a rotational motion when the winding mechanism is operated.

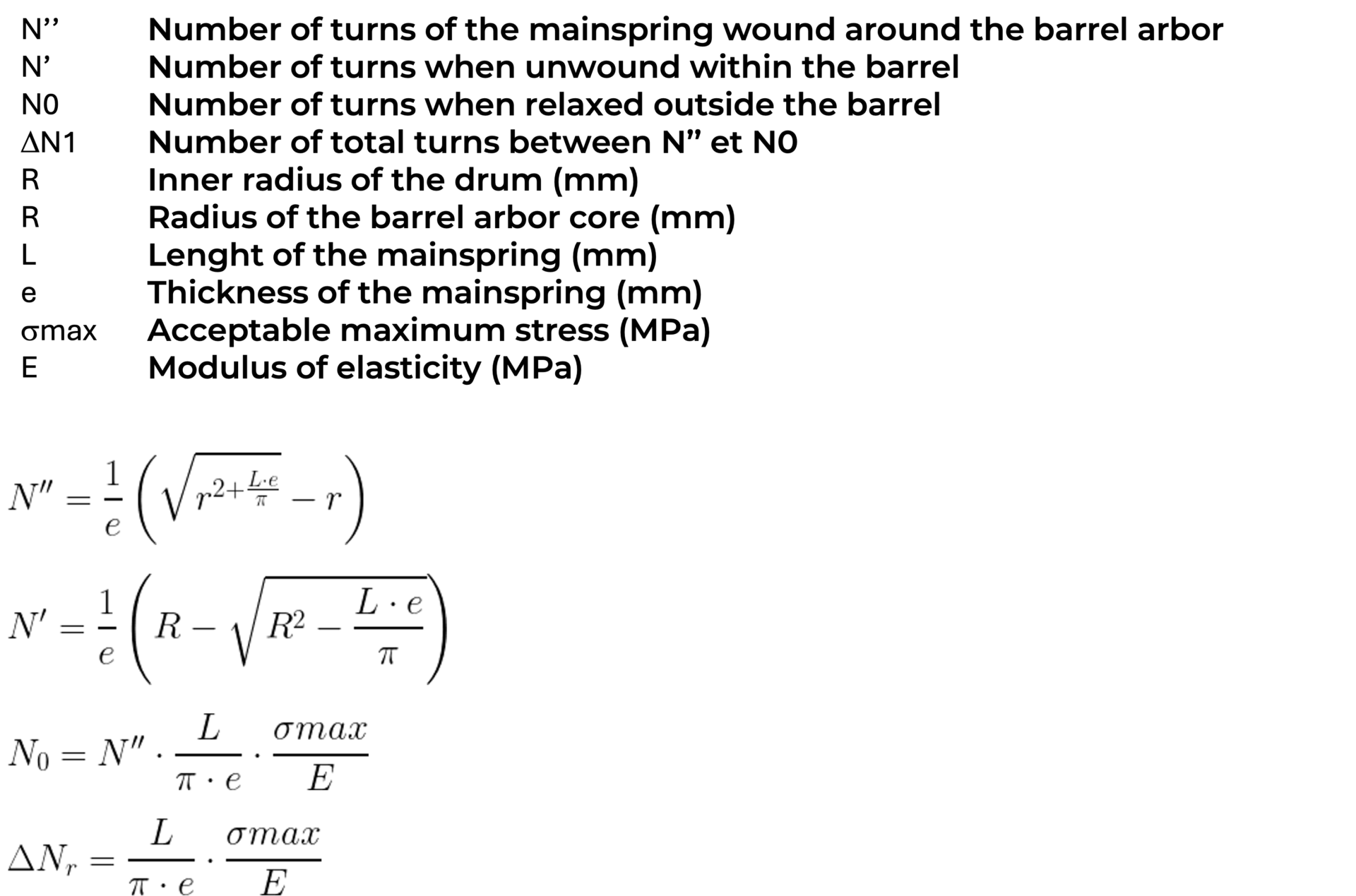

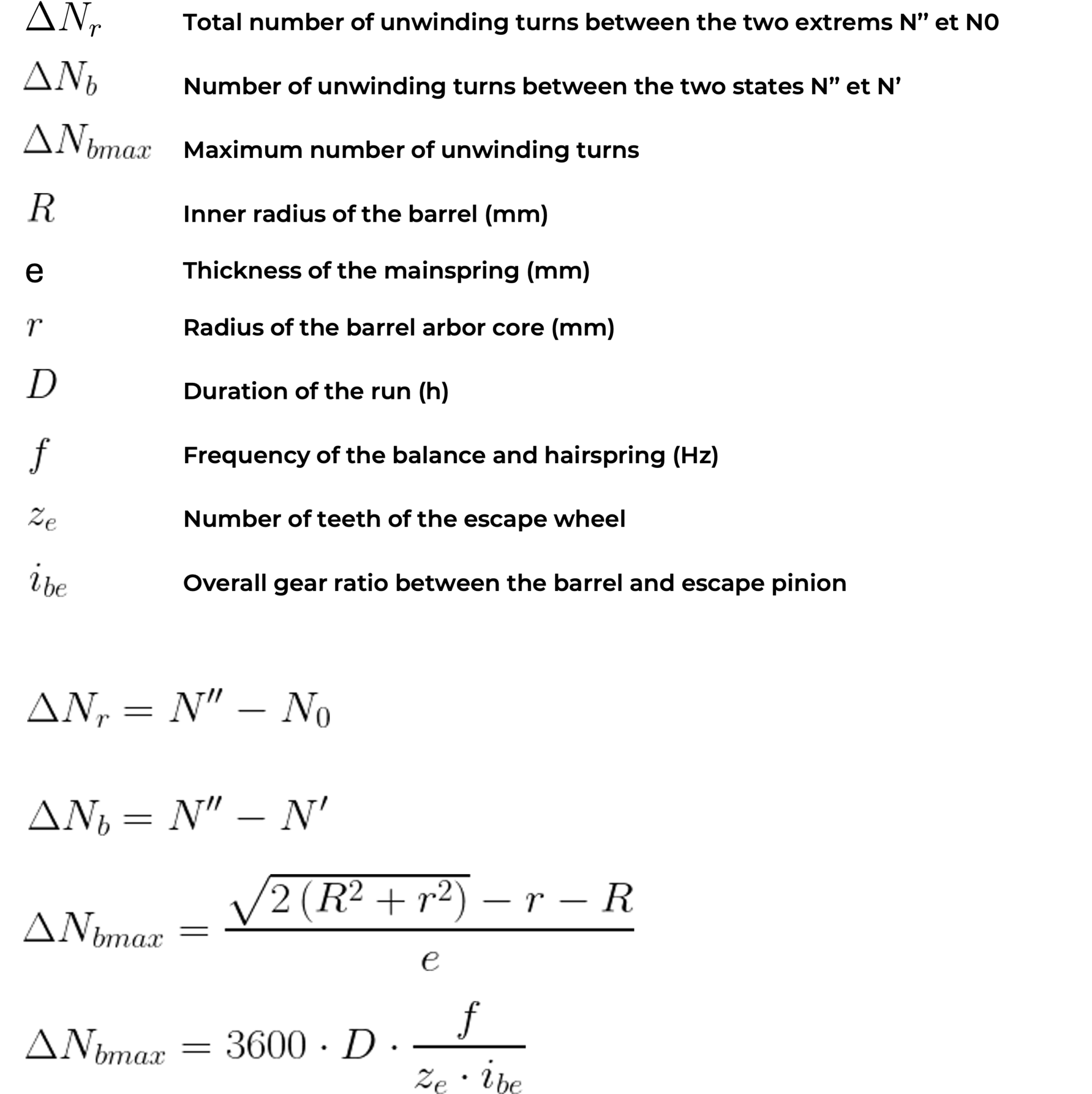

Number of winding and unwinding turns

Calculating the maximum number of unwinding turns of a mainspring

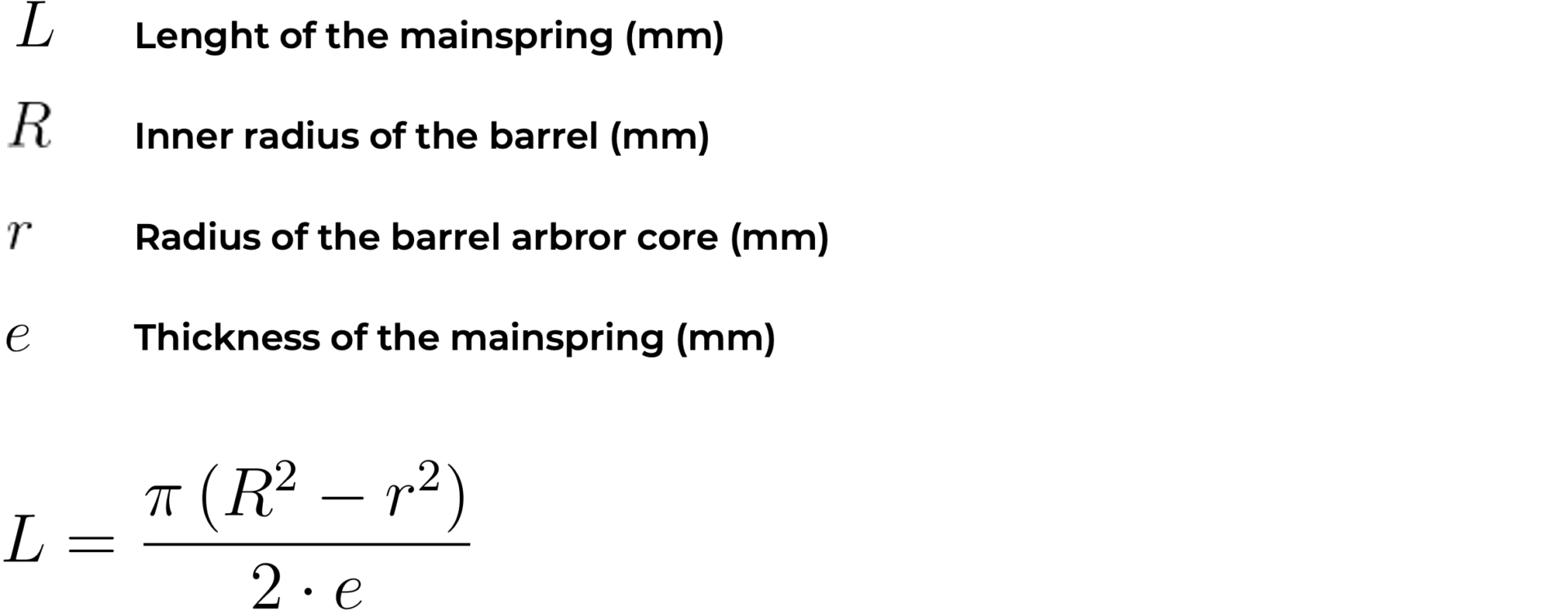

Calculating of the theorical lenght of a mainspring

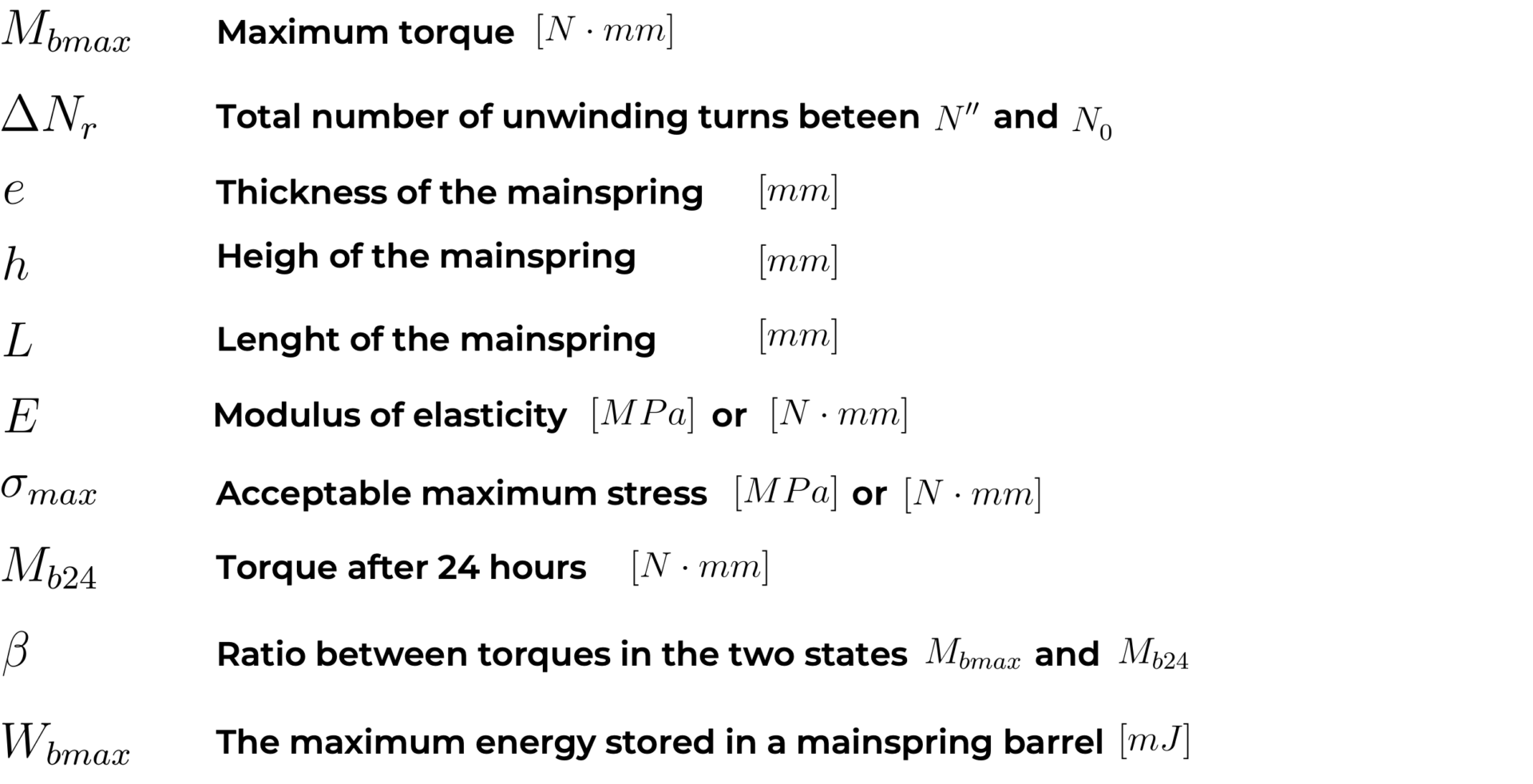

Calculating the tork of a mainspring