SHORT TIME INTERVAL MEASUREMENT

General Overview

The chronograph is a device designed to precisely measure the elapsed time between two events. Its history has been shaped by the influence of several visionary watchmakers who, through their inventions, laid the foundations for the complex mechanism we know today.

- Chronograph or chronometer?

- History and etymology

- Integrated or modular ?

- Column wheel or cam ?

- Horizontal or vertical clutch ?

- Counters and graduations

- Tachymeter, telemeter, pulsometer

Many misunderstandings arise between these two terms. A “chronograph” refers to a short-time measurement mechanism that operates independently of the watch’s time display. On the other hand, a chronometer designates a high-precision timepiece that was historically certified by chronometric observatories and is now regulated by the international ISO 3159 standard.

Etymology of the word « chronograph »

The term “chronograph” originates from Ancient Greek, where “chronos” (χρόνος) means “time”, and “graphein” (γράφειν) means “to write”. A chronograph is an instrument designed to literally “write” time. This meaning was reinforced with the invention of the inking chronograph by Nicolas Rieussec in 1821, where a stylus marked the passage of time by leaving a visible trace on a rotating disc. This innovative mechanism established Rieussec as a pioneer of the chronograph as we know it today. Given this historical context, it would be more precise to refer to modern chronographs as “chronoscopes”, since they display elapsed time rather than physically recording it.

History of chronograph

Louis Moinet (1768-1853)

The French master watchmaker Louis Moinet is recognised as one of the early inventors of the chronograph. His “Compteur de Tierces” was developed several years before Rieussec’s invention.

In 1816, Moinet designed a high-precision chronograph that measured elapsed time to an astonishing 1/60th of a second. To achieve this, he created a regulating organ oscillating at 30Hz—an exceptional frequency compared to the 3–5Hz of modern mechanical watches. While such a high frequency posed challenges in terms of lubrication, power reserve, and component wear, Moinet’s work laid the foundations for highly precise time measurement in practical applications.

Nicolas Rieussec (1781-1866)

Rieussec Chronograph

A defining moment in chronograph history came in 1821, when Nicolas Rieussec, a French watchmaker, invented the inking chronograph. To address a specific need in horse racing, Rieussec developed a mechanism in which a stylus left an ink mark on a rotating disc every time it was activated, providing a visible record of elapsed time. This was a major breakthrough, solving a problem that traditional clocks could not address with precision.

At this stage in its development, Rieussec’s chronograph featured only start and stop functions—there was no reset mechanism. Resetting the device required manually replacing the graduated paper disc mounted on the rotating dial.

Frédérick-Louis Fatton (1812-1876)

Another key figure in early chronograph development, Fatton, was an apprentice of Abraham-Louis Breguet. Just like Rieussec, he received Breguet’s encouragement and in 1822, just months after Rieussec’s invention, he patented a fixed-dial inking chronograph. In this mechanism, a moving hand with an ink reservoir — rather than a rotating disc — was responsible for marking time.

Who invented the chronograph?

Attributing the invention of the chronograph to a single watchmaker is nearly impossible, as many horologists contributed to its development. A definitive list of innovators would be exhaustive, but among the most significant contributors are John Arnold, Abraham-Louis Breguet, Joseph-Thaddeus Winnerl, Abraham-Louis Perrelet and Adolphe Nicole, who introduced such mechanisms as a hand which returns to zero, integration of an independent seconds hand to a movement, the monopusher chronograph, the split-seconds chronograph.

From Rieussec’s inking mechanism to Winnerl’s independent reset, these pioneers each played a vital role in the evolution of horology, refining and enhancing precision timing mechanisms that are still fundamental to modern watchmaking.

A chronograph is a short-time measurement mechanism that operates in addition to the traditional watch movement, which is designed to display the time.

There are two main approaches to chronograph construction. The first approach involves integrating the chronograph mechanism in the base movement from the outset. This means the movement is exclusively dedicated to chronograph watches. An integrated chronograph is generally regarded as more authentic and of higher quality than an additional mechanism.

The second approach involves using a traditional movement designed for hours, minutes, and seconds display and adding a separate module containing all the components required for the chronograph function.

This modular construction offers key advantages, such as lower development costs compared to integrated chronographs, greater flexibility as a module can be fitted onto different base movements, and versatility as the same base movement can accommodate various complication modules.

The various functions of the chronograph, including start, stop, return to zero and split-second, are controlled by a cam system, which exists in two types:

The column wheel is a circular cam featuring a ratchet toothing at its base and a variable number of vertical pillars, known as columns. With this mechanism, each press of one of the pushers advances the column wheel by one increment of its ratchet toothing. The coupling levers, hammers, and brakes each have a finger that rests against the circumference of the columns. With every advance of the column wheel (each press of a pusher), these fingers will either rest on the top of a column or fall into the gap between two columns, allowing the chronograph components to move in a precisely defined sequence and amplitude. Due to its construction, the column wheel rotates in a single direction.

The cam (or chronograph cam) is generally composed of two or three levels (concentric, interconnected cams), which coordinate all the chronograph functions. Unlike the column wheel, the cam rotates clockwise when activating the start function and counterclockwise when stopping the chronograph. This alternating motion, resembling a back-and-forth movement, is what gives the cam its name. The reset function moves the cam to a third position, releasing the brake and engaging the hammer(s) to return the chronograph hands to zero.

The chronograph draws its energy from the base movement and is typically driven by the movement’s second wheel. As a result, the chronograph mechanism must be engaged with the base movement when in operation and disengaged when stopped. There are two primary engagement methods:

The horizontal clutch was the only system used until the introduction of vertical clutches in the late 20th century. In this mechanism, the pivot of the second wheel extends above the bridge surface, where a driving wheel is mounted. This wheel rotates at the same speed as the second wheel, usually one revolution per minute. The clutch lever, which pivots around the axis of the second wheel and driving wheel, carries the intermediate chronograph wheel (clutch wheel). The driving wheel and clutch wheel are constantly rotating, regardless of whether the chronograph is engaged or stopped.

At the end of the clutch lever, a finger is held against the column wheel under the tension of the clutch lever’s spring. When the start function is activated via the dedicated pusher, the column wheel advances by one step, allowing the clutch lever’s finger to drop into the gap between two columns. This action pivots the clutch lever around its axis, engaging the clutch wheel with the chronograph wheel. Simultaneously, the brake is released, and the chronograph begins measuring time.

This historical and traditional construction is valued for its authenticity, but it has a minor risk of imprecision when starting the measurement. This is due to the travel distance of the clutch wheel before engagement and its constant motion. Because of this, there can be a slight misalignment between the clutch wheel’s teeth and the chronograph wheel’s teeth at the moment of engagement. These limitations led to the development of vertical clutch chronographs.

There are different designs of vertical clutches, but the general principle involves stacking the clutch wheel above the intermediate chronograph wheel or directly above the chronograph wheel so that they rotate concentrically. When the chronograph is activated, the clutch wheel moves vertically, engaging with the intermediate or chronograph wheel by sliding along its axis while remaining driven by the second wheel. Between these two components, a clutch spring and friction plate ensure perfect and instantaneous engagement, to eliminate the risk of misalignment and ensure precise chronograph activation.

A chronograph displays, at a minimum, the measurement of seconds. This is typically indicated by a central hand, ensuring greater readability and precision. The second scale is usually divided into smaller increments, corresponding to the frequency of the watch’s regulating organ.

For example, a regulating organ oscillating at 18,000 vibrations per hour (2.5Hz) results in the chronograph hand advancing in 5 increments per second, providing a precision of 1/5th of a second. While a movement oscillating at 5Hz divides the second into 10 increments, offering a 1/10th of a second precision.

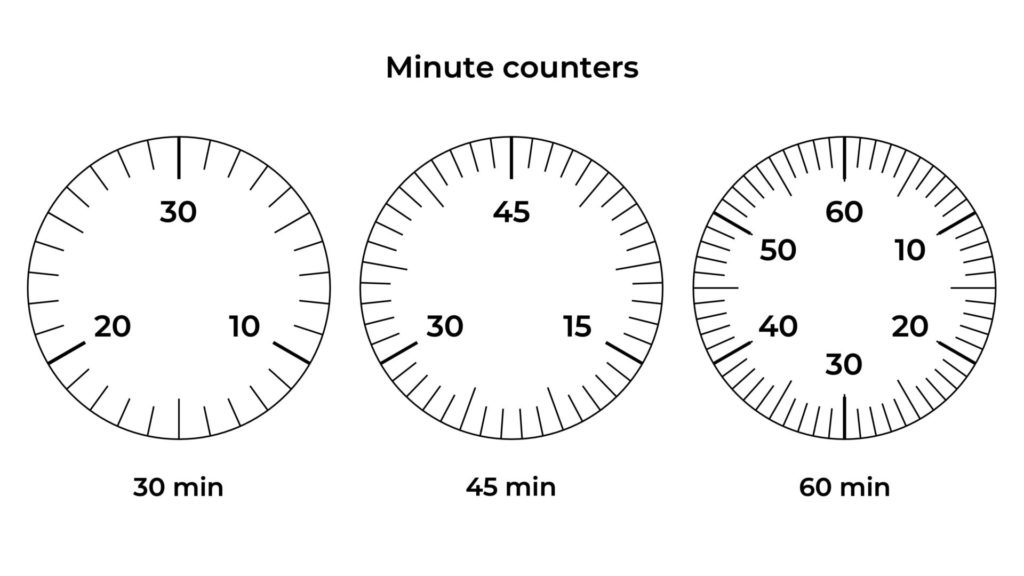

The chronograph seconds are frequently complemented by a minute counter (totalizer). Although this counter can be centrally displayed, it is most commonly found on a subdial. Each time the chronograph hand completes a full revolution (one minute), the minute counter advances by one increment. Minute counters are often graduated for 30, 45, or 60 minutes.

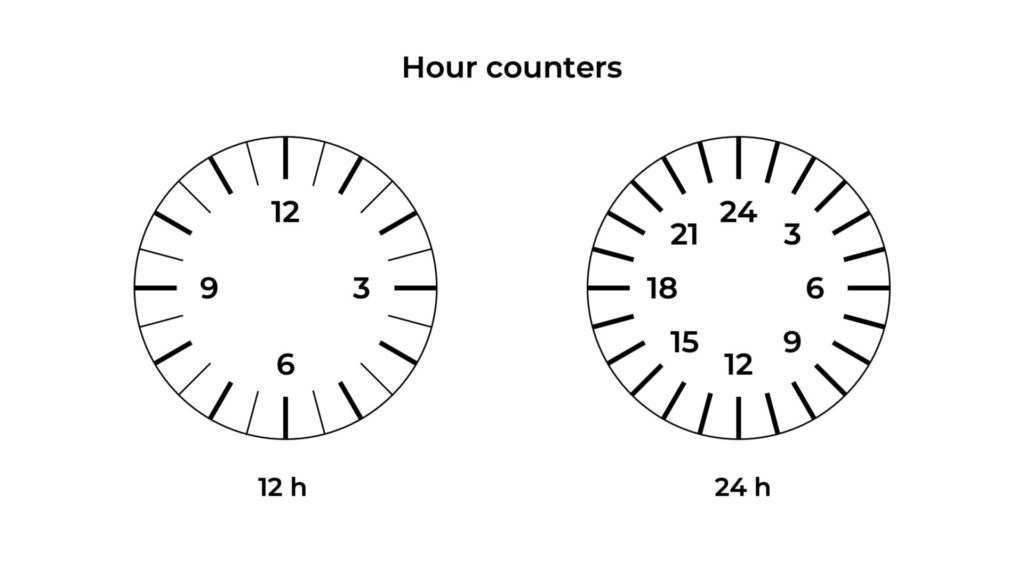

The minute counter is often paired with an hour counter generally displayed on its own subdial, marked with either 12-hour or 24-hour graduations.

The progression of the minute and hour counters can be dragging, semi-instantaneous, or instantaneous, depending on the movement’s construction.

Various conversion scales or even calculation rules can be displayed concentrically around the chronograph’s seconds scale. These markings can be engraved or pad-printed on the dial, inner flange, or a fixed or rotating bezel.

The telemetric scale is used to measure distance based on the speed of sound and has historically been used primarily in military applications. For instance, it can determine the distance travelled by a cannonball after being fired. The chronograph starts when the explosion is seen and stops when the sound of the explosion is heard. In the example below, a 7.4-second delay means the explosion occurred 2,5 km from the launch point. Due to the necessity of both seeing the event and hearing it (even at a long distance), aside from estimating the distance of a lightning strike the telemeter has few other practical applications.

The tachymeter scale is used to measure speed or pace. It requires a reference distance. For example, a reference of typically 1 km is needed to measure the speed of a car. Many highways have distance markers spaced exactly 1 km apart. If a car takes 21.5 seconds to cover a 1 km distance, the tachymeter scale would indicate a speed of 167.4 km/h.

Similarly, a machine’s hourly production rate can be determined by timing the manufacturing of a single unit. If one cycle takes 12 seconds, the machine produces 300 pieces per hour.

DOUBLE-PUSHER CHRONOGRAPH

This is the most common construction. The three chronograph functions — start, stop, and reset — are controlled by two pushers, usually positioned on either side of the crown. Various mechanisms will be described in this chapter.

FLYBACK CHRONOGRAPH

This mechanism was developed for aviation pilots, enabling them to measure consecutive time intervals without delay during approach procedures. When the chronograph is running, a single press of the reset pusher simultaneously performs the stop, reset, and restart functions, allowing for immediate transition to the next measurement with a single action.

SPLIT-SECOND CHRONOGRAPH

This type of mechanism features two superimposed, concentric chronograph seconds hands and a third pusher. When the split-second pusher is activated, one of the chronograph hands stops, allowing for the reading of an intermediate or split time, while the other hand continues running. Pressing the split-second pusher again causes the stopped hand to “catch up” with the moving hand, resuming synchronised operation.

MONOPUSHER CHRONOGRAPH

As its name suggests, all functions of this type of chronograph are controlled by a single pusher. The three chronograph phases — start, stop, and reset — occur in sequence with each press of the pusher, cycling continuously.

BECOME A CONTENT CONTRIBUTOR

HOROPEDIA is a participative knowledge platform and we invite all those who wish to contribute to this adventure of sharing watchmaking knowledge to join us.

It can be additional explanations, images or other illustrations or terms not yet identified that deserve to be.