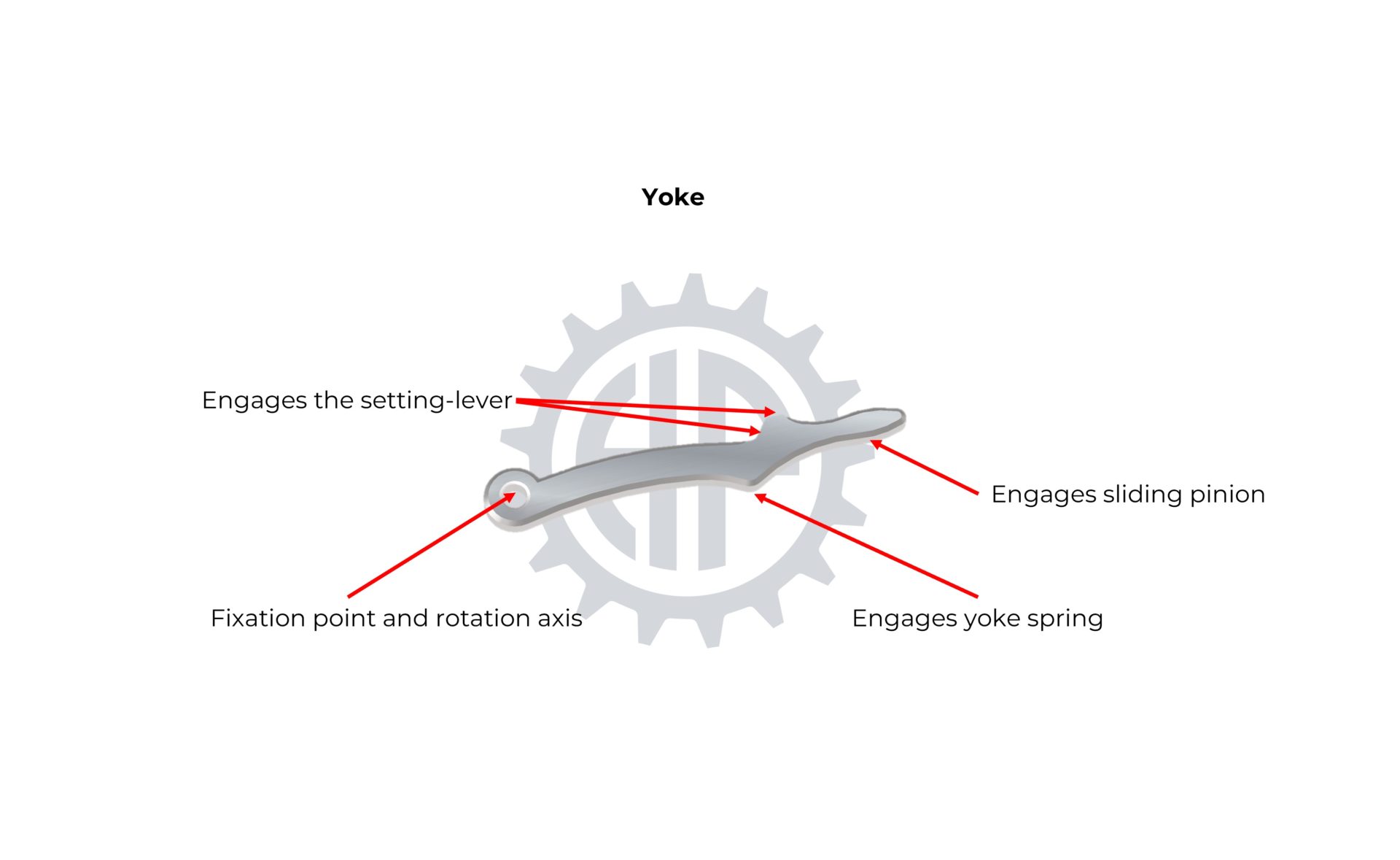

YOKE

The yoke is a component shared by the winding and time-setting mechanisms. It is the element that allows for the switching of the winding stem control between these two mechanisms. This is a lever pivoting on a tenon embedded in the plate at one end. The other end of the yoke is housed in the groove of the sliding pinion. When activated, it compels the sliding pinion to slide on the winding stem to switch between functions (winding) and (time-setting) and vice versa.

The yoke emerged in 1847 with the invention of the setting lever mechanism by Antoine Le Coultre, of which it is the central element. Since then, it has allowed for the switching of the crown control between the winding and time-setting mechanisms, at a minimum. The major advancements made to Le Coultre’s invention have aimed to multiply the functions adjustable by the crown. As a result, the function of the yoke and its profile can be more or less complex.

The watchmaker begins the artisanal production of the yoke by engraving its profile using a tracer point on the surface of a steel plate slightly thicker than the finished component. Next, the watchmaker marks the drilling points for the screw and pivot. Then, the contour of the yoke is delicately cut using a jeweler’s saw. The sides of the piece are then filed to bring the yoke to its final thickness and in absolute accordance with its form. The yoke is then angled and polished using customary tools (files, burnishers, polishing). Following the artisanal techniques, the watchmaker subsequently draws out the lines on the sides of the piece (satin finish) and the small flat portion that remains on the upper surface of the yoke.

When the yoke is close to its final dimensions, the watchmaker adjusts the function that connects the yoke to the setting lever by pre-assembling the two components to the plate. More than the measurement of a plan, this is typically an action where the watchmaker’s eye and hand remain the best tools. Heat treatments and blanching operations follow, and the yoke is then ready to be assembled.

The electrical discharge is used to optimize production costs for a single piece or a small series of components. The implementation costs and machine processing time remain relatively low and suitable for small production volumes. Additionally, this technology allows for the cutting of complex and fine profiles without exerting any mechanical stress on the component during its fabrication. Compared to the artisanal method, electrical discharge cutting offers considerable time-saving with positive impacts on the decoration stages. The end of the manufacturing and decoration process resembles the artisanal method or the required level of finishing.

For large-scale production, the investment in a stamping tool justifies manufacturing yokes at an optimal cost. The expanded outline of the profile is thus stamped directly into a strip of steel slightly thicker than the finished component by a stamping press. Manual steps, however, remain unavoidable. The yoke must be brought to its final dimensions (profile and thickness) while providing the desired finishes and decorations (satin finish, beveling, etc.).