THIRD WHEEL

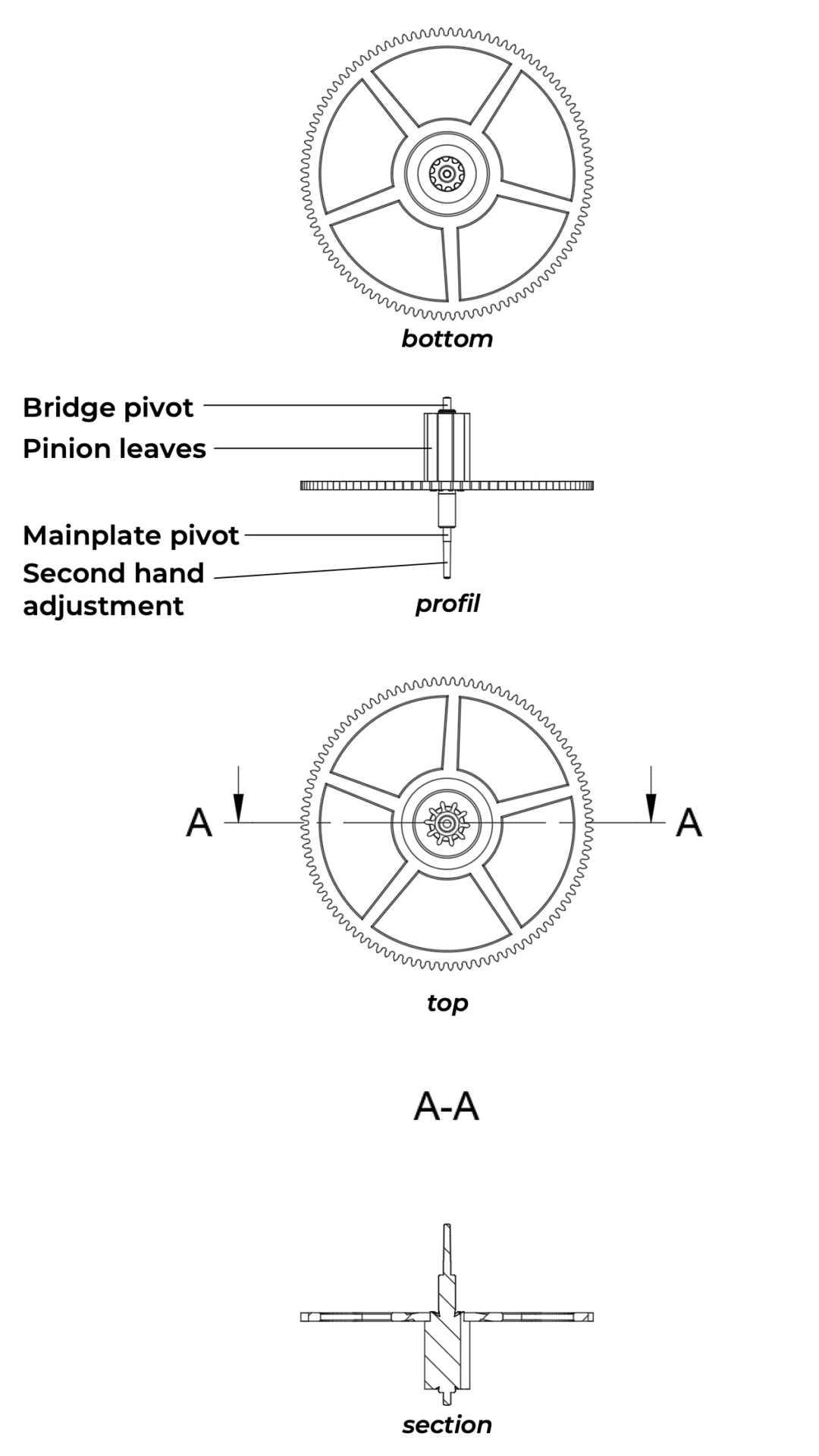

Figure 1: Plan of an assembled third wheel

The third wheel is a component of the counting and transmission organ, responsible for dividing time into elementary units and, depending on the construction, enabling the display of the seconds. Driven by the second wheel, it transmits the energy it receives to the escape pinion.

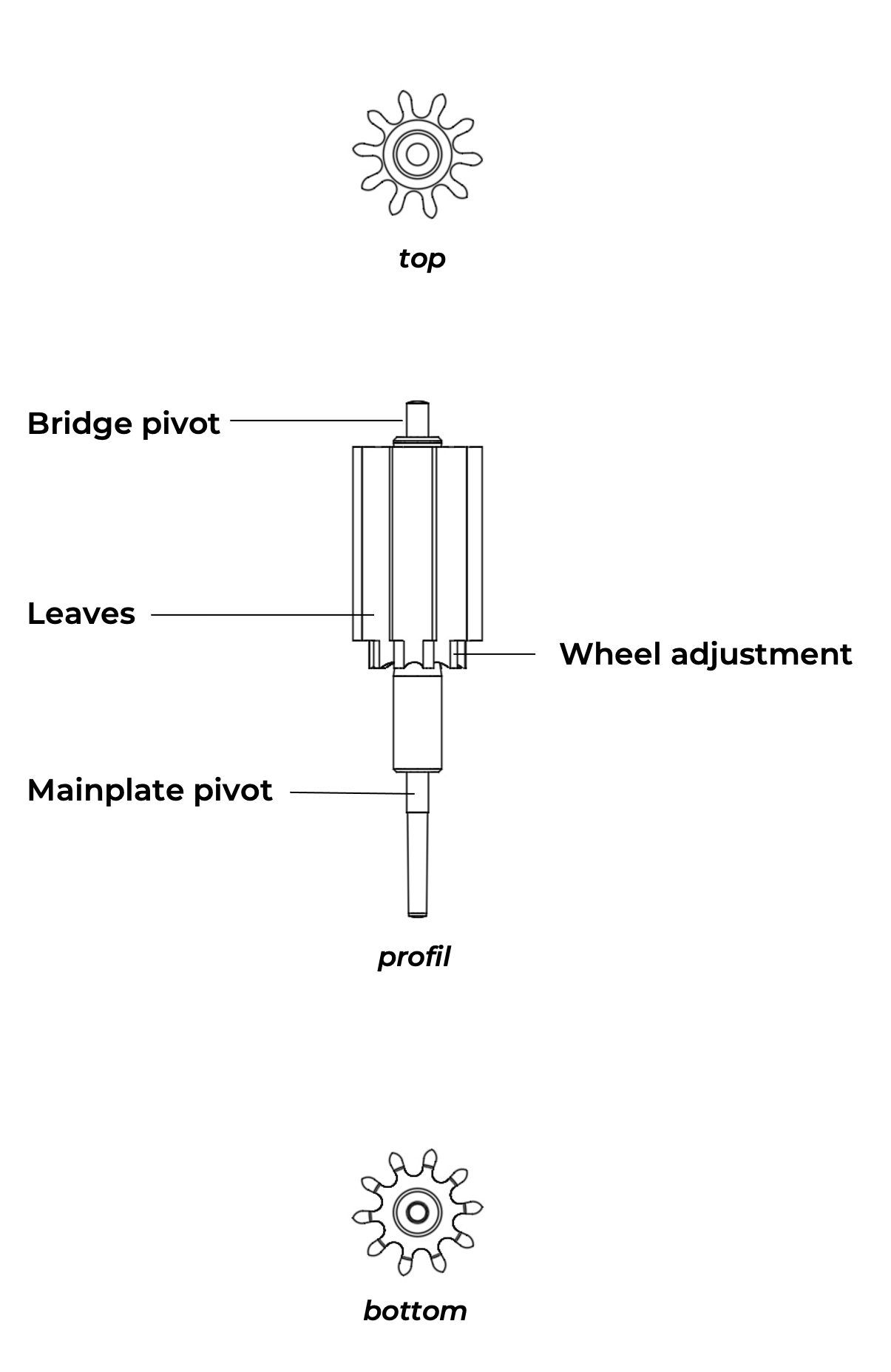

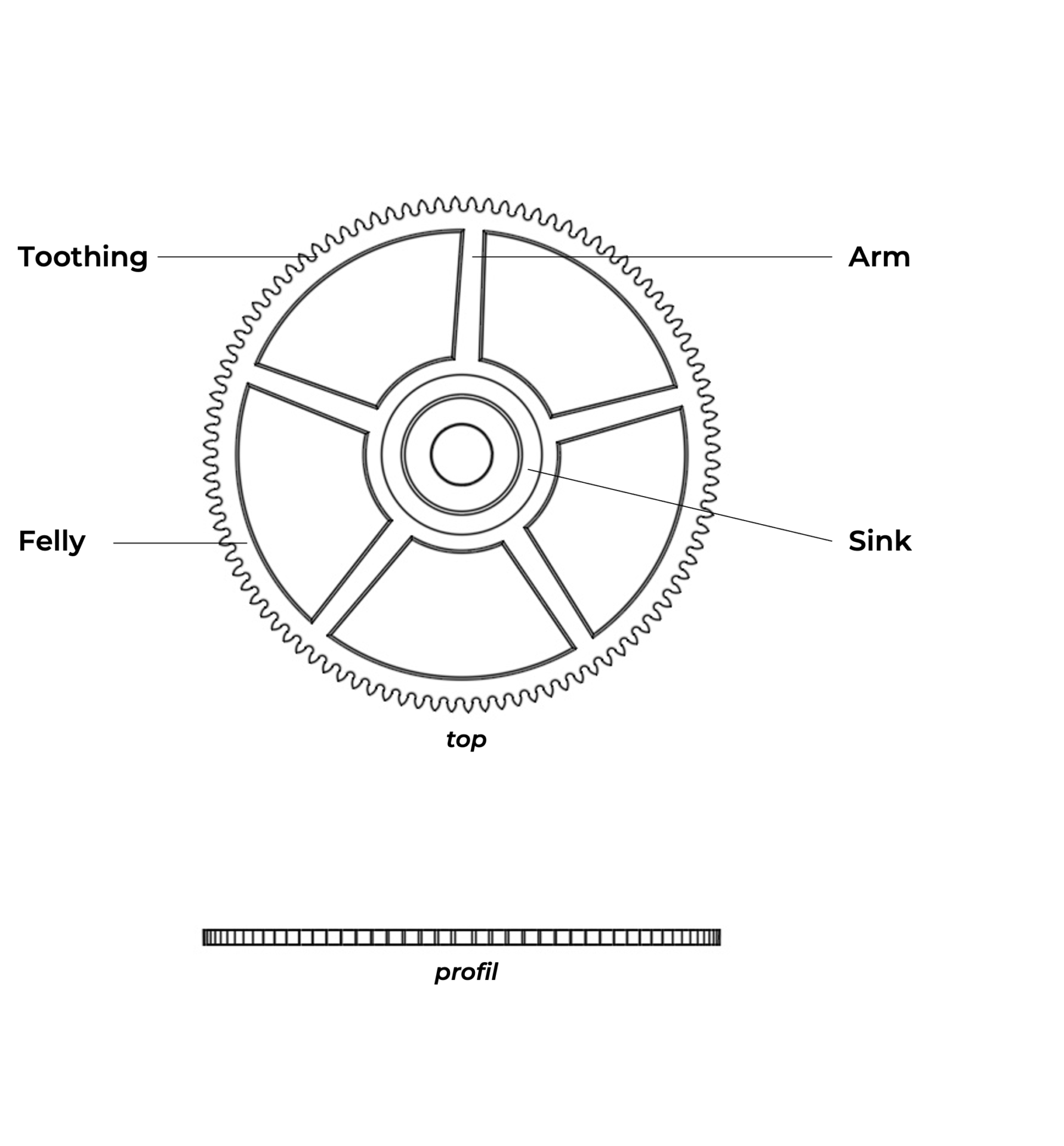

The third wheel is composed of two inseparable parts:

-

Third pinion: Driven by the second wheel.

-

Third wheel: Driving the escape pinion.

Materials and construction

As with the other wheels of the train, the third wheel is generally made of gilded brass, machined or stamped with high precision, then smoothed and bevelled according to the degree of finishing required. The pinion, made of hardened and polished steel, forms the axis of the wheel. The wheel is firmly riveted to the pinion, creating a perfectly solid assembly.

Typology of third wheels

- Watches without a seconds hand

When a watch does not display the seconds, the third wheel is not required to rotate at a fixed speed. Its role is then to pace the speed of the train so that the centre wheel completes one revolution in one hour, as part of the overall gear ratio of the gear train. The dial, therefore, displays only hours and minutes. - Third wheel with seconds hand

When the movement is designed to display the seconds, the third wheel must complete one full revolution in one minute. Two display configurations are possible:

- Off-centred seconds (small seconds)

In this configuration, the seconds hand is off-centred in relation to the movement and to the display of hours and minutes. The dial then includes a small counter, usually positioned at 6 o’clock but sometimes at 9 o’clock or 3 o’clock. The construction is straightforward: the pinion of the third wheel, already present in the normal gear train, is simply extended by a staff passing through the mainplate to carry the seconds hand. No additional transmission is needed. Only the positioning of the third wheel must be chosen to ensure the seconds are displayed in the desired place. - Central seconds

The central seconds display requires a more complex modification of the train. Since the third wheel is not located at the centre of the movement, additional wheels must be added to bring the seconds display to the centre. The most common solution consists of extending the arbor of the third pinion with a staff so that it projects from its bridge. A wheel blank, known as the chamfered wheel, is fitted onto the staff of the third pinion. This wheel drives an intermediate wheel, which in turn drives the central seconds wheel. The central seconds wheel passes completely through the centre wheel, within which it pivots. A simple gear ratio between the chamfered wheel and the central seconds wheel ensures that the latter rotates at the desired speed of one revolution per minute. This construction requires careful stacking and an additional set of wheels, which increases both assembly complexity and sensitivity to friction.