THE ROLLER

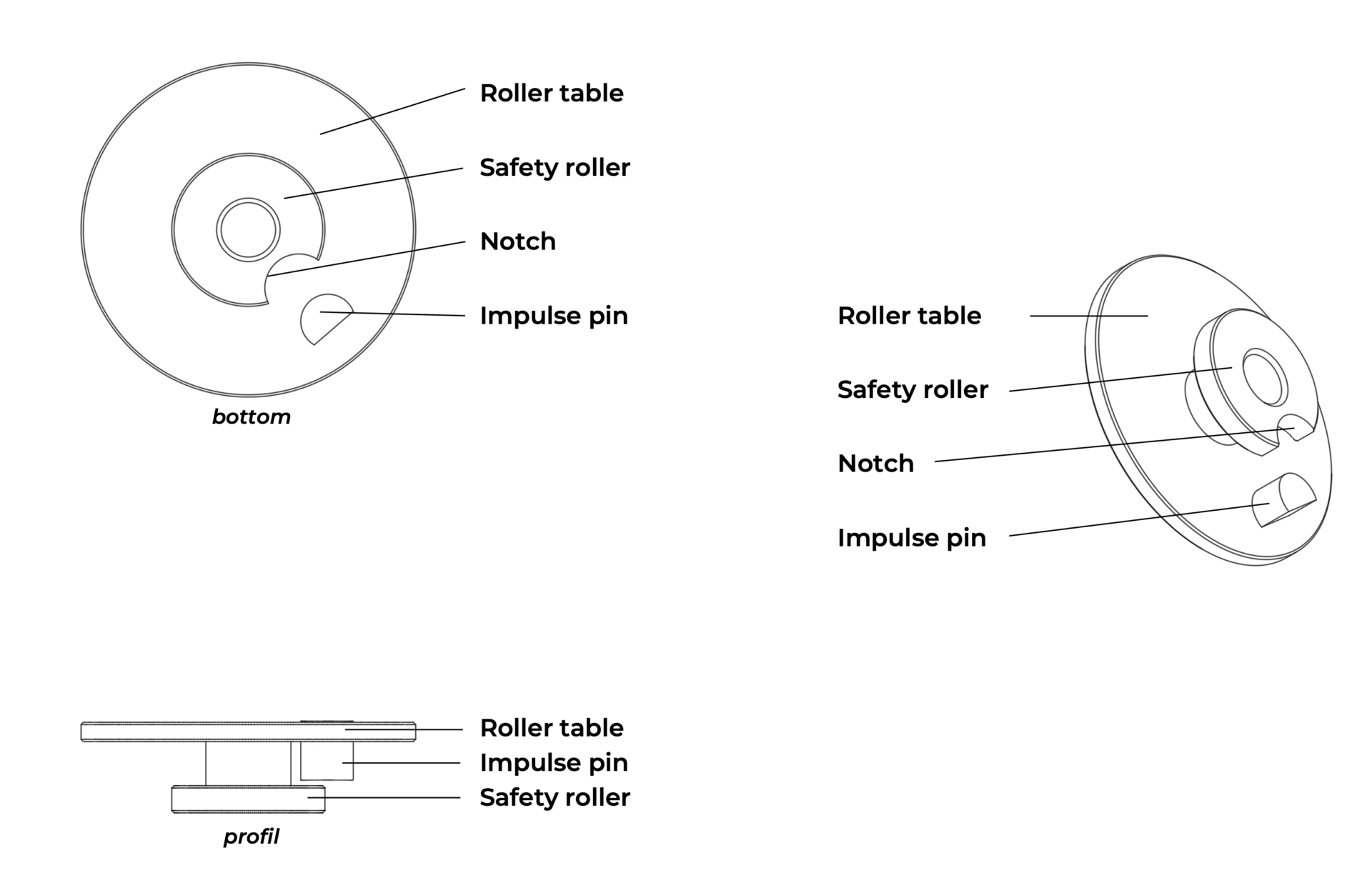

Figure 1: Plan of a roller

Figure 2: Exploded view of an assembled balance wheel

Figure 3: Operation of the Swiss lever escapement (real speed)

Definition and Function

Although it is fixed to the balance staff (part of the regulating organ) (see figure 2), the roller actually belongs to the Swiss lever escapement (see figure 3), which is a distribution organ that controls the transmission of energy from the counting and transmission organ (gear train) to the regulating organ (balance wheel and hairspring).

The roller consists of three distinct elements:

-

The roller table, which carries the impulse pin (also called the roller jewel).

-

The impulse pin, which performs the unlocking phase and receives the impulse from the pallet fork during its interaction with it.

-

The safety roller, located beneath the roller table and connected to it by a hub. Its interaction with the guard pin of the lever acts as a safety device, preventing overbanking. An elliptical notch is cut into the circumference of the safety roller, aligned with the impulse pin. This notch is called a passing hollow and allows the guard pin to pass freely during the unlocking and impulse phases, enabling the lever to move from one banking pin to the other only during these two phases.

Although the roller table, safety roller, and hub are described as separate functional elements, they are usually machined as a single piece and are referred to as a double roller.

Function within the Swiss Lever Escapement

In the operating cycle of the Swiss lever escapement, the roller plays a crucial role in the following phases:

-

Unlocking (impulse initiation): At the end of the balance’s supplementary descending arc, the impulse pin strikes the pallet fork, causing the lever to rotate.

-

Impulse: Once unlocking has occurred, the escape wheel transmits energy to the lever, which in turn engages the impulse pin, imparting energy to the balance wheel for the next oscillation.

-

Safety action: The circumference of the safety roller acts as a stop for the guard pin when the balance executes its supplementary arcs, both ascending and descending. This prevents the lever from accidentally jumping from one banking pin to the other due to shocks, a phenomenon known as overbanking.

(For further detail, see the section on the functioning of the Swiss lever escapement)

Materials

Traditionally, the roller is machined from hardened steel, brass, or glucydur. The impulse pin is made of synthetic ruby.

Assembly and Adjustment

The roller is friction-fitted onto the lower part of the balance staff, beneath the balance wheel (see figure 2). This delicate operation requires a staking tool and a precisely sized punch, ensuring that the roller is neither deformed nor damaged. During fitting, the impulse pin must be aligned midway between two balance arms (or directly between two adjacent arms).

(For further details, refer to the section “Fitting the Roller” in the film dedicated to adjustment)

Conclusion

The roller is a vital component in the functioning of the Swiss lever escapement. Although it is mounted on the balance staff and thus mechanically connected to the regulating organ, it is essential to remember that THE ROLLER IS A CONSTITUENT ELEMENT OF THE DISTRIBUTION ORGAN, not of the regulating organ.

Thomas Mudge invented the Swiss lever escapement in 1754. This type of escapement has remained by far the most widely used since the beginning of the 20th century. The roller naturally appeared alongside the invention of this escapement, and its construction and function have remained virtually unchanged ever since.

The impulse pin, made of synthetic ruby, cannot realistically be produced by traditional artisanal means due to the nature of ruby synthesis, machining, and polishing processes. Regardless of the material used, the roller is typically manufactured by turning and presents no particular production challenges. Once machined, the roller is fully polished, typically through a tribological process. Rollers made of brass or glucydur are then nickel-plated or rhodium-plated to protect them against oxidation.

The impulse pin is fitted into a milled recess in the roller table specifically designed for this purpose and is then secured in place using shellac or adhesive.