BARREL

Artisanal production of a barrel drum

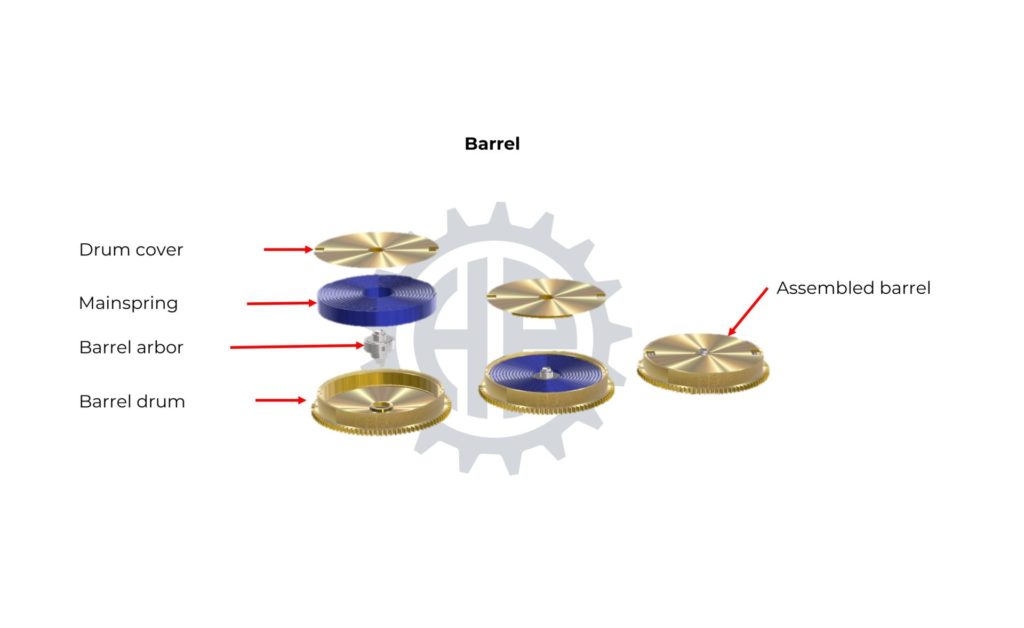

The barrel is a set of several components, usually four in number: the barrel drum, the cover of the barrel drum, the barrel arbor, and the mainspring.

The role of the barrel is to store the energy accumulated during the winding (manual or automatic) of the watch and gradually release it to the movement.

To assemble the barrel, the relaxed spring is placed inside the drum. The mainspring is a spiral-wound steel blade capable of developing considerable force given its size. The barrel-arbor is then placed in the centre of the drum. The inner coil of the mainspring is attached to the arbor by a hook system (on the arbor) and notches. The assembly is then closed with the cover that fits onto the barrel drum.

The role of the barrel arbor is twofold. During winding, it allows the spring to be wound around its circumference (and thus at the centre of the drum) to arm the spring and give the watch its full autonomy. During watch winding, the winding mechanism drives the ratchet wheel, which is fitted onto a machined square at one end of the shaft. The barrel arbor also serves as the axis and pivot for the barrel, allowing it to rotate freely. The mainspring is thus held to the barrel arbor by a hook system, and its other end is fixed (by a notch and a bridge system) to the inner wall of the barrel drum, thereby putting the spring under tension.

The force exerted by the spring on the drum wall, once armed, tends to rotate the entire barrel around its axis when the spring seeks to unwind. Teeth are milled on the larger diameter of the drum. This gearing allows the centre pinion to be driven, consequently followed by the entire kinematic chain of the movement.

Once fully wound, the spring reaches its maximum tension. If the winding mechanism is then forced, it inevitably causes the mainspring to break. Thus, as early as the 17th century, mechanisms for limiting winding (finger, Maltese cross, etc.) were introduced. It’s a system that blocks the winding mechanism just before the mainspring reaches its maximum tension.

Unfortunately, such a setup does not apply to watches equipped with an automatic winding system. The mechanism of the automatic system is unable to detect the over-tensioning of the mainspring or to stop supplying it when the spring reaches its maximum tension. To prevent the mainspring from breaking in such a situation, automatic watch springs are equipped with a sliding bridge. This bridge, located at the outer end of the mainspring, hooks into a notch in the inner wall of the barrel drum. When the spring slightly exceeds its maximum tension, the bridge, through its construction and the shape of the drum’s notch, comes out of its notch and slides along the inner wall of the drum before hooking into the next notch (several notches are made on the inner wall of the drum). Once the watch is fully wound, the movements of the wearer of an automatic watch keep the spring at maximum tension. The barrel thus distributes maximum and constant energy, ensuring a better quality of regulation.

To mitigate the risk of mainspring breakage, many manual-winding watches today are equipped with an “automatic” type spring, allowing endless winding without any danger.

While the manufacture of the drum, its cover, and the barrel arbor does not pose great difficulty, the production of springs requires very specific equipment and expertise. Their production is systematically subcontracted, and only a few manufacturers share this market.

The quality of a barrel essentially depends on its spring. This spring should have optimal efficiency (minimizing energy loss for an increased power reserve) and develop a force as constant as possible throughout its deployment (precision of the movement). Precise calculations, incorporating the nature of its alloy, dimensions, and thermal treatments, allow to production of a high-performance and suitable barrel.

To increase the power reserve and/or achieve a more constant force throughout the entire work of the watch, the number of barrels can be multiplied. Similar to an electrical circuit, a series arrangement of barrels will increase the power reserve, while their parallel operation will distribute more constant energy throughout the duration of their work.

Due to the robustness and comfortable dimensions of its arbor, the barrel easily lends itself to a suspended construction, meaning that the barrel is fixed to the mainplate by a single end of its axis. The use of a barrel bridge is therefore no longer necessary and often allows for minimizing the thickness of the movement and improving its aesthetics. The recent development of micro-ceramic ball bearings allows this type of construction to achieve quite satisfactory efficiency.

The barrel has existed since the early days of watches and has always been the essential source of energy for mechanical watches. Before the invention of the winding mechanism, winding was done with a key directly positioned on the barrel arbor, allowing it to be driven by a square. In the 18th and 19th centuries, suspended barrels without their usual bridge were frequently found. With generous dimensions, the barrel drum then became a favoured platform of expression for decorators (engravers, enamellers, gem-setters, etc.). Over time, barrels, and particularly mainsprings, have continued to improve. Their alloy has gained in performance (elasticity, constant development, friction limitation, etc.), and their calculation (appropriate sizing for established criteria) has improved, as have their methods and production tools.

Mainsprings have always been produced by artisans and then specialized companies. Today, they are only produced through industrial processes. Today’s artisan will therefore source the mainspring from a specialized manufacturer. However, they can easily machine the other three components of the barrel (the steel arbor, the drum, and its cover usually made of brass) on a simple lathe, where they can also proceed with the tooth cutting of the drum and the decoration of the three components.

Regardless of the manufacturing method of the movements and the watches to which they are intended, mainsprings have always been produced by artisans and, later, specialized companies. Today, they are only produced through industrial processes. The mainspring is made from strips of material (steel alloy). These steel strips will undergo numerous rolling and heat treatment operations (annealing). These operations will allow the spring to reach its final dimensions (length, height, thickness) and impart its mechanical properties (elasticity, flexibility, hardness). The notch for the barrel arbor is stamped, and the bridge is riveted at the other end of the blade. The next step is to give the spring its final shape. It will then be wound around an axis (estrapade) and undergo further heat treatments to fix this shape.

The other components of the barrel can be easily made using an automatic lathe, on which the drum’s tooth cutting can also be performed. For better efficiency, however, it is preferable to perform the cutting on a dedicated machine (gear cutting machine) that will provide much more precise cutting. Once the components are finished and decorated, the barrel can be assembled. This operation is carried out on an industrial scale (T-0).