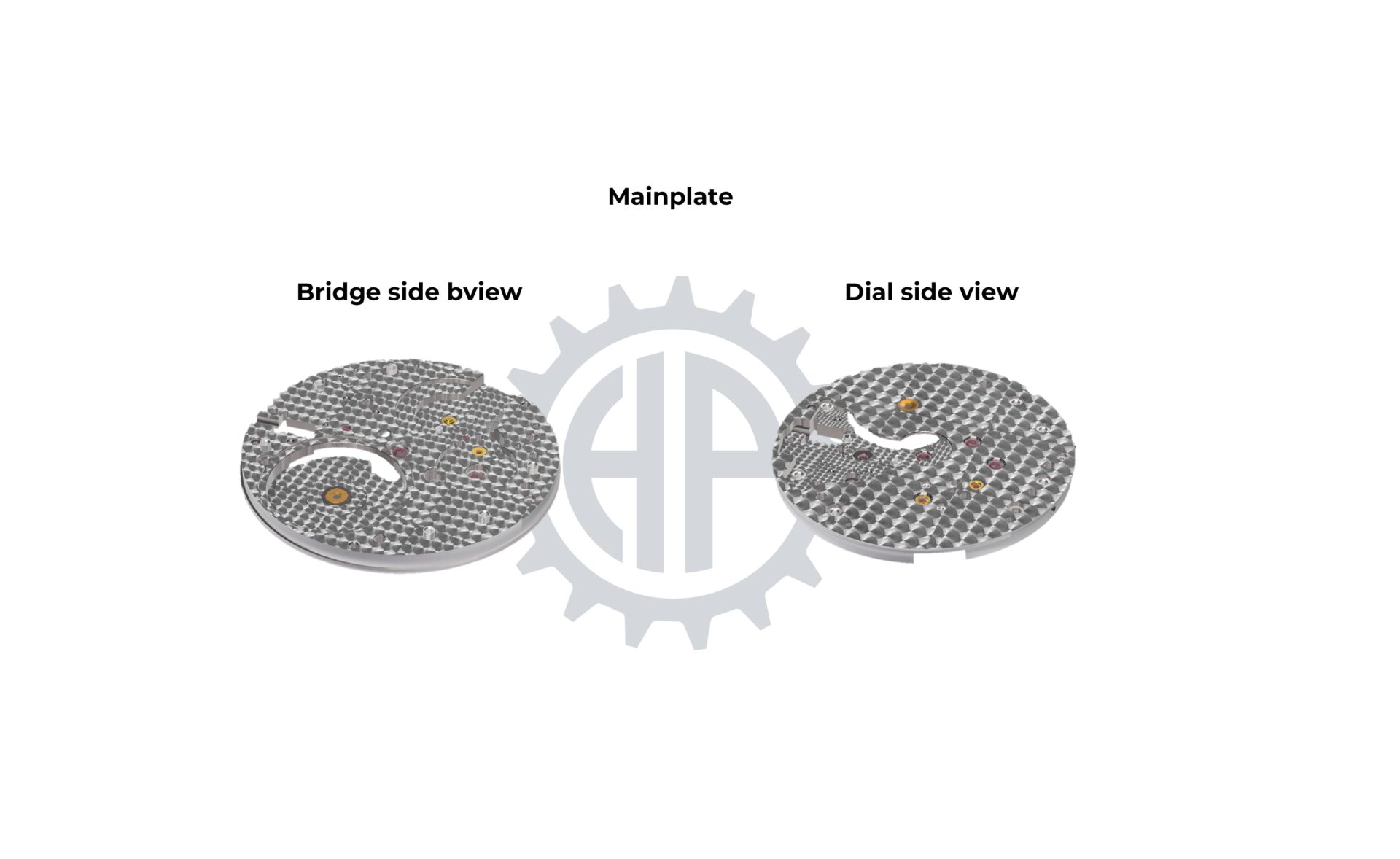

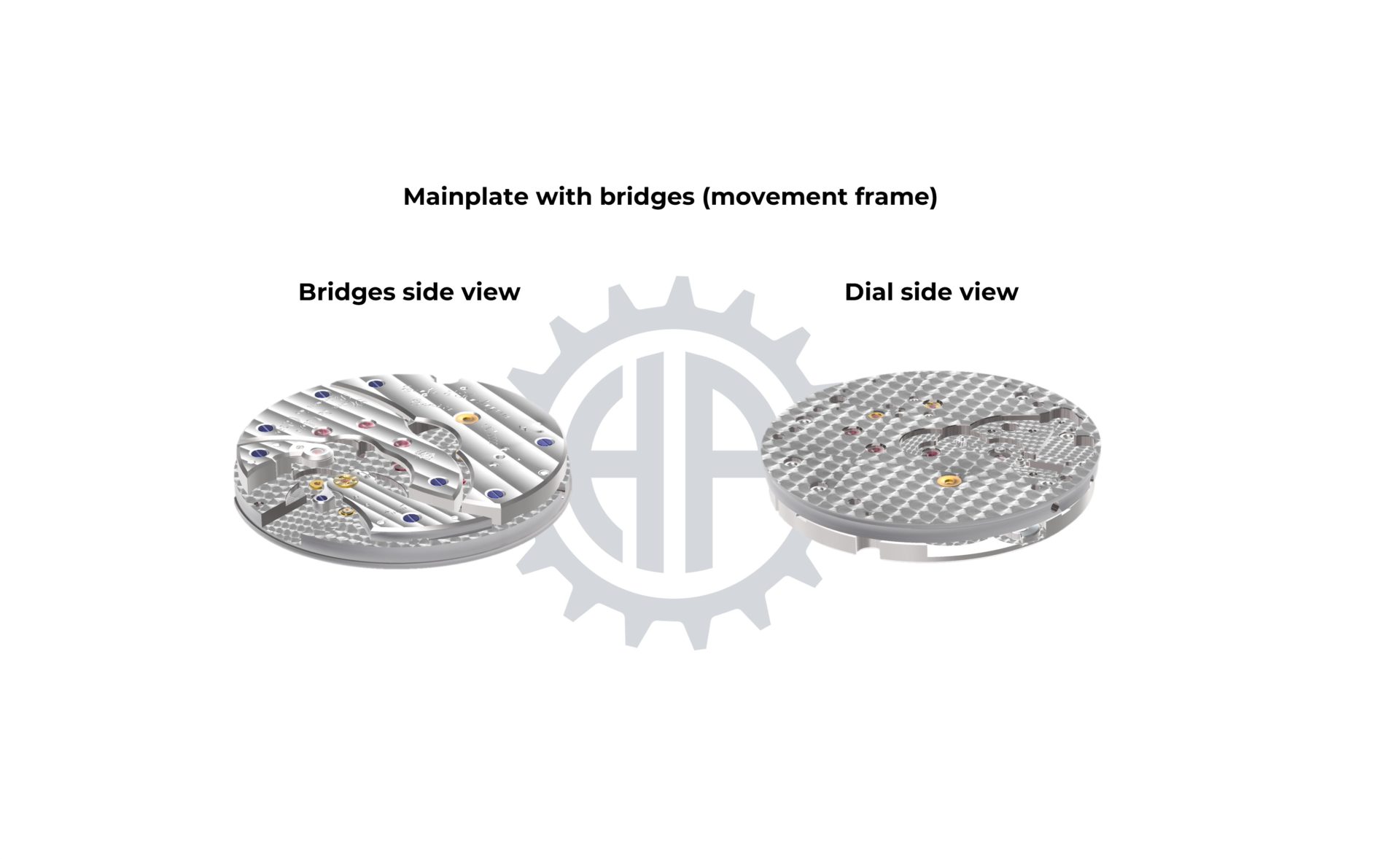

As the main support for assembling movement components, the mainplate serves as the framework and primary element. Together with the directly attached bridges, they form the movement frame. It is between the mainplate and the bridges that the mobile elements of the movement are freely secured. They can pivot around their axis between jewels (stones) (barrel, gear train, balance wheel, etc.) or around a machined or set pin in the plate (time-setting yoke, crown wheel, etc.). Some fixed elements (springs, plates) can be assembled there by screwing, setting, or even welding or bonding.

To ensure perfect interaction among all fixed components, a plate must provide maximum rigidity and the lowest possible expansion coefficient. The plate can be made from diverse materials such as brass, nickel silver (or German silver), gold, sapphire, carbon, etc.

Like bridges, the mainplate can benefit from a wide range of artisanal (hand engraving, openwork & skeletonizing, beveling, etc.) or industrial decorations. Traditionally, galvanic treatments (gilding, rhodium plating) protect brass plates from oxidation. Nowadays, hi-tech surface treatments (PVD, DLC, CVD, ALD) offer an expanded range of colours and specifications.

Although the plate is usually round, it can take various shapes, typically to match the design of the case to which it is destined (barrel-shaped, rectangular, oval, etc.).

The manufacturing technique of mainplates has evolved significantly. Once crafted on face-lathe, during the industrialization era they started to be produced with lathes and milling machines powered by hydraulic and later electric forces. In the 20th century, these machines became automatic (mechanical programming of operations by cams). Finally, the advent of IT introduced the first CNC machining centres (multi-purpose machines capable of milling, turning, and drilling) with digital control of the entire manufacturing protocol. Auxiliary artisanal (stamping) or modern and industrial techniques (laser engraving, machining, electrical discharge, etc.) can, in some cases, complement or substitute the manufacturing process.

Historically, mainplates were made of brass or nickel silver. Very similar in composition, these alloys offer mechanical properties ideal for machining and decoration. Appearing in the early 19th century, nickel silver (or German silver) is an alloy of brass (copper and zinc) with added nickel. It has a silvery colour and resists corrosion so well that it does not require galvanic treatment (such as rhodium or gold plating). Since the late 20th century, various synthetic or composite materials have been used to fabricate mainplates, including synthetic corundum (synthetic sapphire), ceramics, carbon, etc.

The mainplate’s diameter defines the movement’s calibre and is still measured in lines (a medieval unit of measurement, 1 line = 2.255mm).

Usually, the master’s or manufacturer’s hallmark, the calibre number (model name), and the individual movement number are engraved or stamped on the mainplate.

There are several methods and different tools that can be used in the artisanal production of the mainplate.

Before machining the mainplate, the watchmaker must perform an important step that requires absolute precision. For optimal movement performance, the axis of each component must be perfectly positioned relative to the others. Centring is done using a centring machine, which defines the centres of various holes and turnings to be made later.

With the centres defined, the watchmaker can proceed to the numerous drillings (axis of mobile components, posts, screw holes, feet, etc.). They will now be perfectly positioned, allowing optimal indexing of the face-lathe for different turning steps.

The face-lathe is the artisan’s tool par excellence. It is a miniature bench lathe that the watchmaker typically fixes in a vice. The watchmaker first manually adjusts the depth of the cut. Then, simultaneously, he starts to operate a chisel that drives the lathe and a second chisel that moves the graver. By combining the rotation speed of the mainplate and the movement speed of the graver, the watchmaker adapts the combination of these two speeds with their sensitivity to achieve precise dimensions and finishes, ensuring both aesthetics and proper functioning.

A bench lathe or a mechanical bench lathe often replaces the face-lathe. The use of such a machine does not compromise the artisanal aspect of the method. It offers a relative timesaving compared to the face-lathe and achieves the same technical and aesthetic quality.

The emergence of machining centers and their widespread use since the late 20th century have imposed them as the main production tool for mainplates. While some artisans or prototypists still use artisanal methods, most mainplates are produced with CNC machining centres. Generally, these machines can perform all machining operations required for crafting a mainplate (milling, drilling, tapping, etc.). Depending on the needs and technical specifications of the mainplates, machines may have different capacities (3, 4, 5, and 6 axes). A conventional mainplate can usually be perfectly machined on a 3-axis machine. While this machining method, due to the setup and implementation time it requires, favours the profitability of large-scale production, it is also appreciated for small series and even in prototyping for its versatility and “standardization” of use.

According to the range of timepieces, some or all decoration operations may be performed during machining operations. Today, one can diamond-cut an angle or mill Geneva stripes on the same machine that machined the mainplate, during the same work cycle. High-end production often relies on more artisanal decoration methods (trimming, beveling, engraving, etc.).

According to industrial practices, once entirely machined and decorated, the mainplate will receive a surface treatment to protect it from oxidation and enhance its aesthetics.

While galvanic treatments (rhodium plating, gilding, etc.) are still widely used, physical vapour deposition treatments (PVD, DLC, etc.) are becoming more prevalent. These treatments have reached an optimal level of quality, being harder and thus less vulnerable to impacts and scratches than a galvanic treatment. They offer an expanding range of colours while perfectly reproducing galvanic shades.

Before accommodating all movement components, the mainplate must first be pre-assembled. All the “fittings”, such as jewels, posts, and feet, should be fixed on it. The entirety of these operations (industrially called T-0) can be performed by watchmakers assembling the movement, specialized operators, or even be fully automated.

Hi-tech technologies can be implemented for certain manufacturing steps. Electrical discharge or laser cutting, for example, can be useful for perforating, skeletonizing, or decorating. In the case of non-metallic materials (ceramics, plastics, composites, sapphire), injection may precede traditional machining operations. In these cases, machining operations will always require high-tech machines and tools and expertise to meet technical challenges (e.g.: material hardness) and tolerances. Surface treatments (generally subcontracted) are mostly high-tech (PVD, DLC, CVD, ALD, etc.).