HAIRSPRING STUD HOLDER

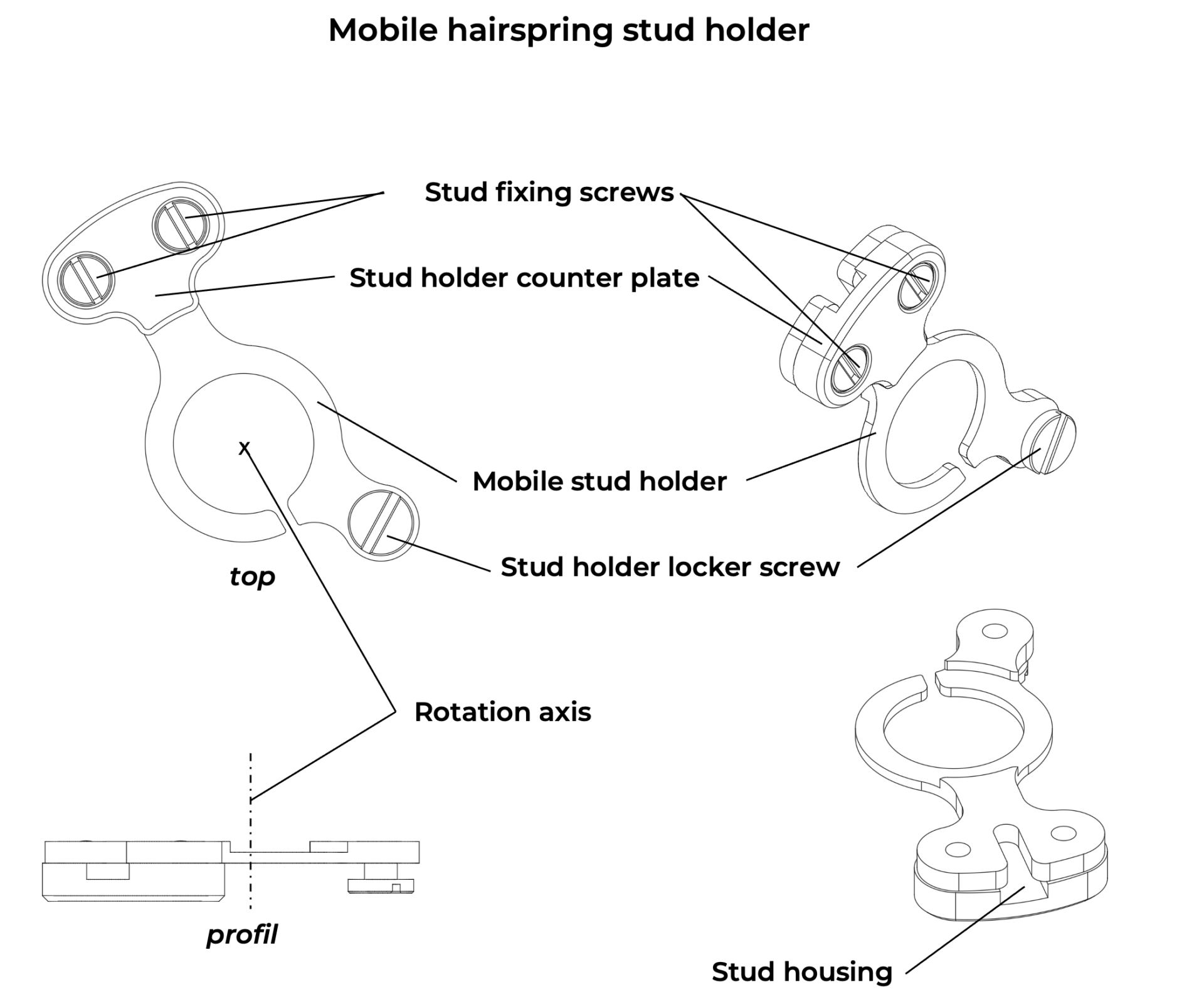

The hairspring stud holder is an optional component, regardless of the type of movement construction or its regulating system. It allows adjustment of the balance’s position of rest, known as the neutral point. The stud holder is a movable element whose axis of rotation coincides with the centre of the balance staff. It is fixed to the balance cock (or balance bridge) in the same way as the regulator index (a friction fit by means of a collet). The stud, itself attached to the outer end of the hairspring, is inserted and firmly secured in the stud holder. By pivoting the stud holder, the balance is displaced angularly. The neutral point is reached when the watch is completely unwound (without any residual energy) and the impulse pin lies on the line connecting the centres of the escape wheel, the pallet fork and the balance.

When the movement is not fitted with a stud holder, the stud is fixed directly to the balance cock (or balance bridge) in a milled groove of its plate.

The patent for the mobile hairspring stud holder, as we know it today, was the result of Camille Calame’s work in 1904. However, the earliest mention of a mobile stud holder dates back to 1889 and is attributed to the German watchmaker Richard Lange.

The watchmaker begins the artisanal fabrication of the hairspring stud holder by marking and drilling the centre of its axis of rotation on the surface of a steel plate slightly thicker than the finished component. The foot of the stud holder is then cut on a lathe, centred on the pivot point of the stud holder. Next, the outline of the stud’s profile is scribed with a tracing point, again centred on its pivot point. The stud is then carefully cut out along the scribed outline with a piercing saw.

The flanks of the part are subsequently filed down to bring the stud to its final thickness, with absolute respect for its intended shape. The stud is then bevelled and polished using standard tools (files, buff sticks, polishing implements). In keeping with best practice, the craftsman then draws out the lines of the flanks (satin-finishing). The thickness of the stud is also calibrated in order to regulate its friction against its collet. This friction must be light enough to allow precise adjustment of the stud’s position, yet sufficiently firm to prevent any accidental displacement, especially in the event of shocks.

To optimise the production costs of a single piece or a small series of components, wire EDM (Electrical Discharge Machining) is particularly advantageous. The set-up costs and machine running times remain relatively low and are suitable for small-scale production. A milling operation to clear the recess in the balance cock (or balance bridge) is then required. Compared with the artisanal method, EDM cutting offers a considerable saving in time, with positive effects on the subsequent decoration stages. The final stages of manufacture and finishing are then carried out either in the same way as the artisanal method or according to the level of finish required.

Because of the relatively complex shape of the stud holder, industrial-scale production generally favours machining on an automatic lathe capable of performing all operations in a single cycle. Finishing and decoration are then carried out either by hand or by industrial means, depending on the desired level of quality. While this method offers the best cost-to-quality ratio, the manufacture of stud holders using machining centres or by stamping is also possible.