MACHINES

From traditional manual workbench machines still often used in some contemporary workshops to the most sophisticated digital machines associated with high technology, this chapter aims to catalogue all the machines used in the watchmaking process. The operating principles of each machine, the advantages and disadvantages they may present, or the materials they use are detailed therein for a better understanding of watch operation and manufacturing.

AUTOMATIC LATHE

The automatic lathe, known as a profile-turning machine, appeared at the dawn of the 20th century, and its automation was initially mechanically controlled by cam systems. Since 1980, electronics and computer technology have enabled the numerical control of automatic lathes, allowing for fully autonomous operation.

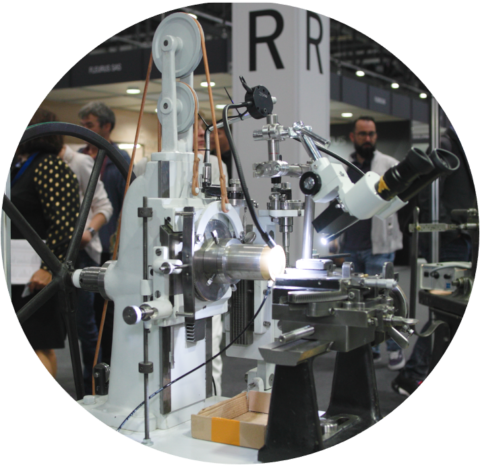

CNC – MACHINING CENTERS

CNC is the acronym for “computer numeric control” and is similar to a multi-axis computer-controlled lathe.

DRILLING MACHINE

Watchmaking predominantly uses vertical drilling machines of various sizes and levels of sophistication, depending on their intended use. Besides drilling, they are commonly used for tapping or decorative work.

ELECTRICAL DISCHARGE MACHINE

An electrical discharge machine allows the machining of conductive metal parts because it uses electricity to machine its parts. It has the advantage of being able to machine several dozen parts one on top of the other and thus be very efficient.

FACE-LATHE

This is a type of hand-operated bench lathe that is particularly valued for machining the contours and recesses of bridges and mainplates.

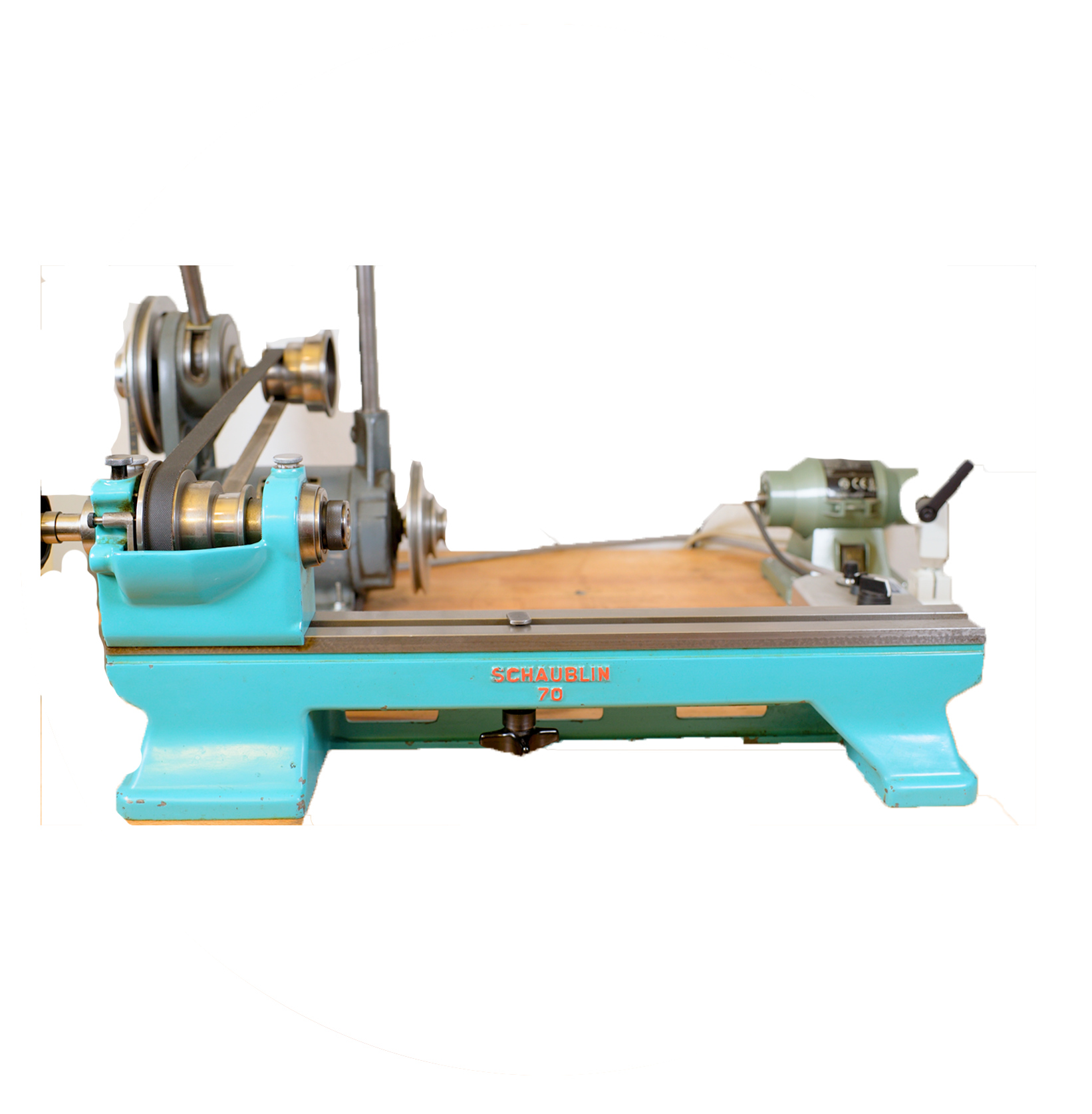

LATHES

Whether manual or electric, a lathe is a machining tool used for producing components primarily of circular forms.

MILLING MACHINE

A milling machine is a motorized machining tool equipped with a rotating spindle that holds the cutting tool (milling cutter), whose form is tailored to the machining to be performed.

ROSE ENGINE LATHE

This is a manually operated machine designed for engraving concentric geometric patterns. The graver is guided by a combination of cams that the rose engine turner selects to define the engraving pattern. Historically, guilloché decoration is mainly applied to casebacks and dials.

STAMPING PRESSES

The stamping presses allow to cut, stamp and bend the material (usually metal) using a die and a punch. Such presses can be operated manually or hydraulically. Depending on their design and intended use, hydraulic presses can be automated and perform sequences of operations by successive strikes (progressive stamping).

STRAIGHT LINE ENGINE LATHE

The straight line engine lathe is a traditional mechanical instrument used in engine turning to engrave linear and repetitive geometric patterns onto metal surfaces, particularly dials and watch cases. Originating in the 18th century, this machine operates through a system of cams, levers, and carriages that allow the controlled movement of a chisel along a rectilinear plane.

BECOME A CONTENT CONTRIBUTOR

HOROPEDIA is a participative knowledge platform and we invite all those who wish to contribute to this adventure of sharing watchmaking knowledge to join us.

It can be additional explanations, images or other illustrations or terms not yet identified that deserve to be.